How does aluminum die casting compare in terms of environmental impact to other casting methods?

01-11-2024Aluminum die casting has several environmental considerations compared to other casting methods, such as sand casting, investment casting, and permanent mold casting.

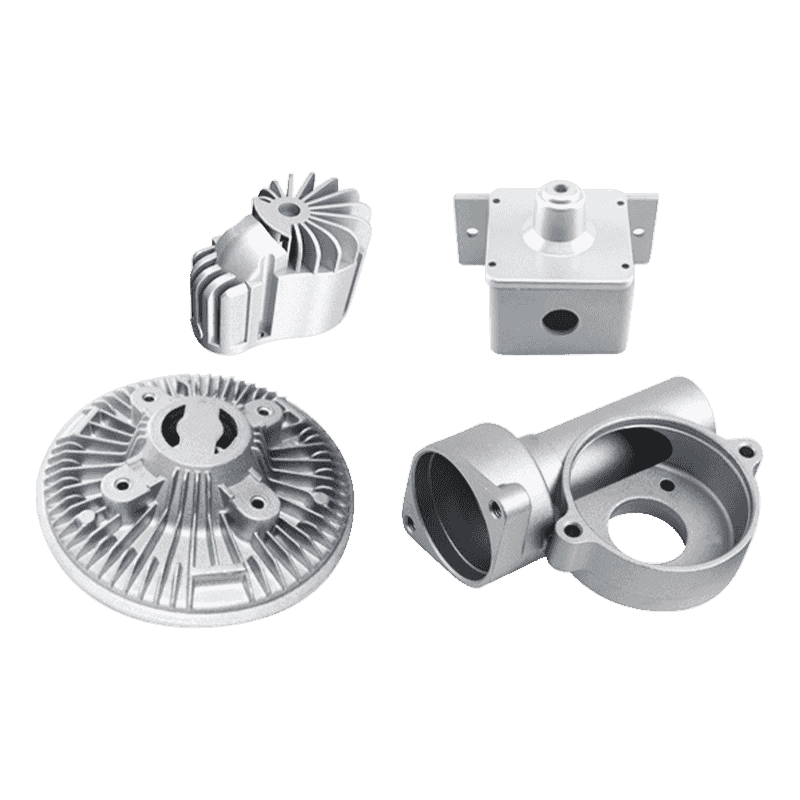

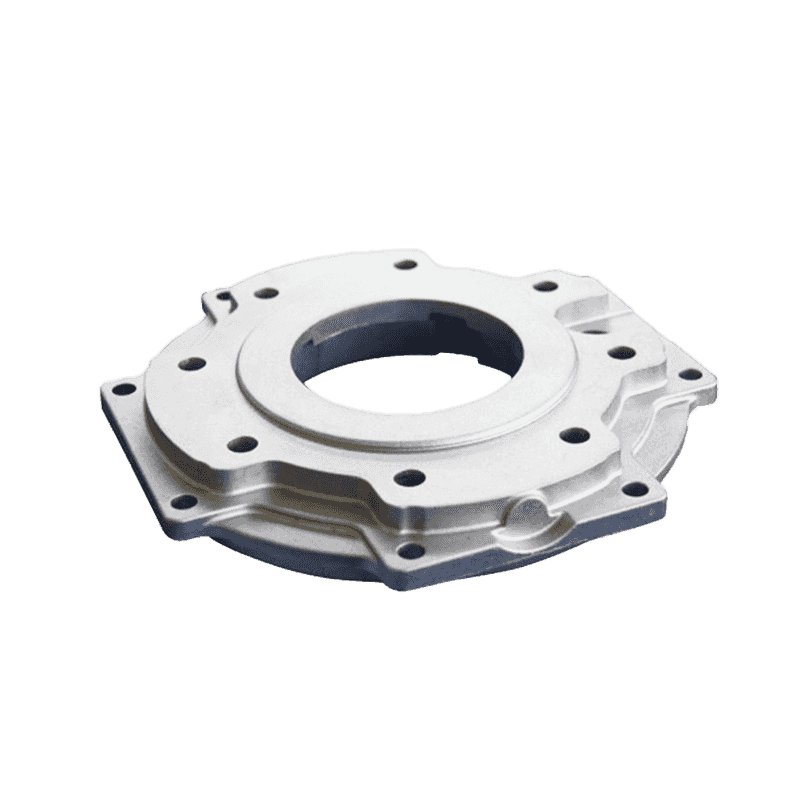

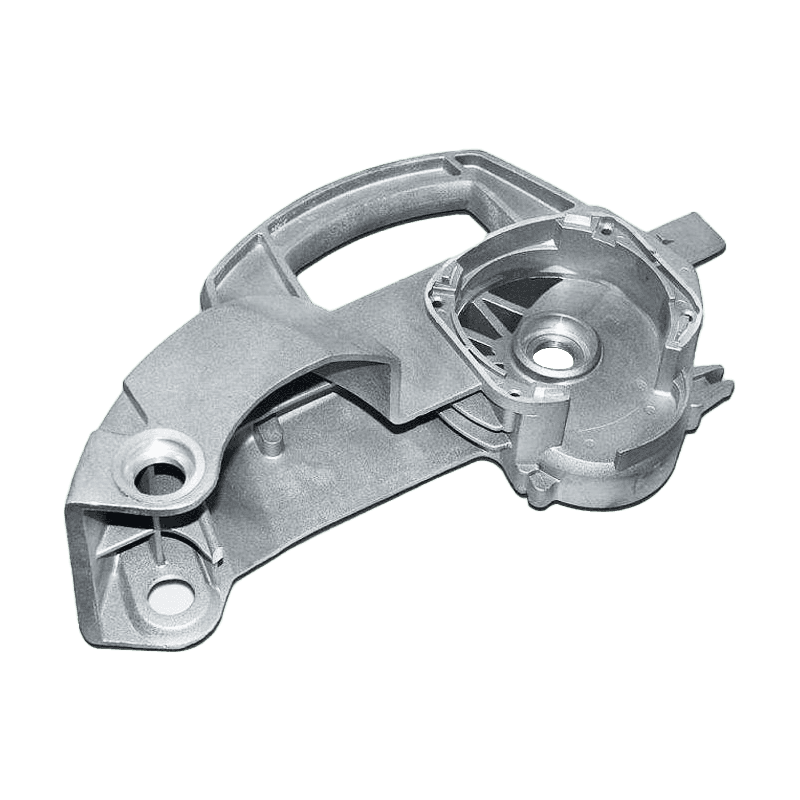

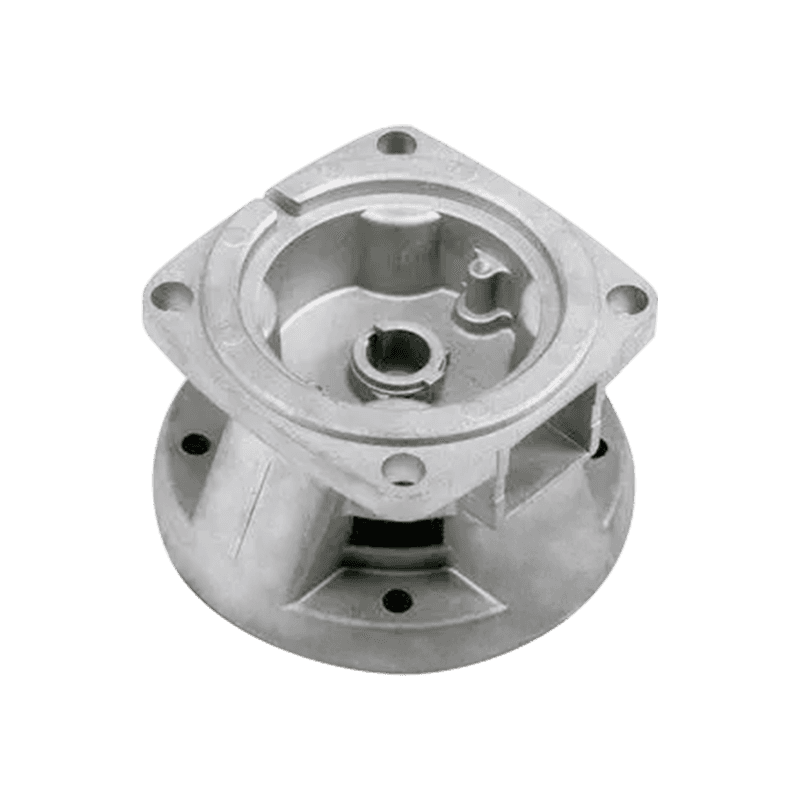

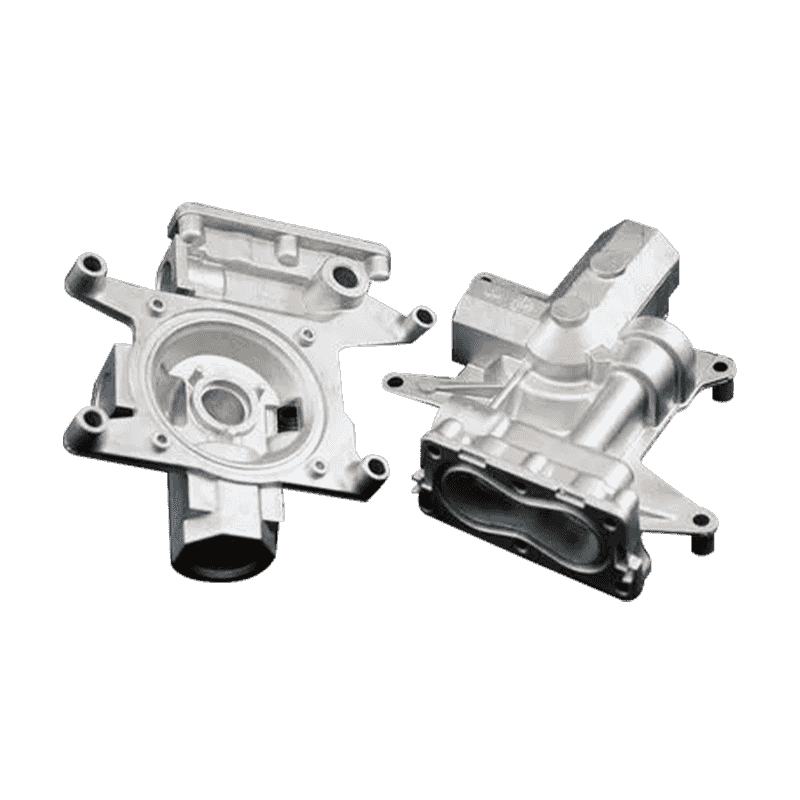

Material Efficiency: Aluminum die casting typically produces parts with less material waste than other methods. The process is highly efficient, allowing for thin-walled designs that minimize the amount of metal used.

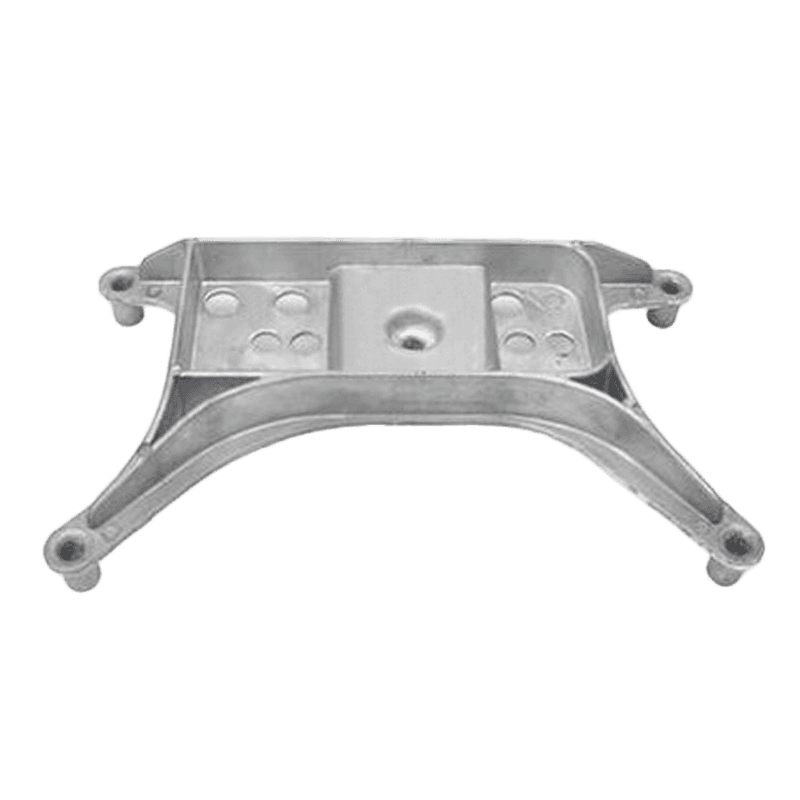

Energy Consumption: While aluminum die casting requires energy for the melting and die-casting processes, it generally uses less energy per unit produced than methods like sand casting. This is due to the rapid cycle times and automation involved in die casting.

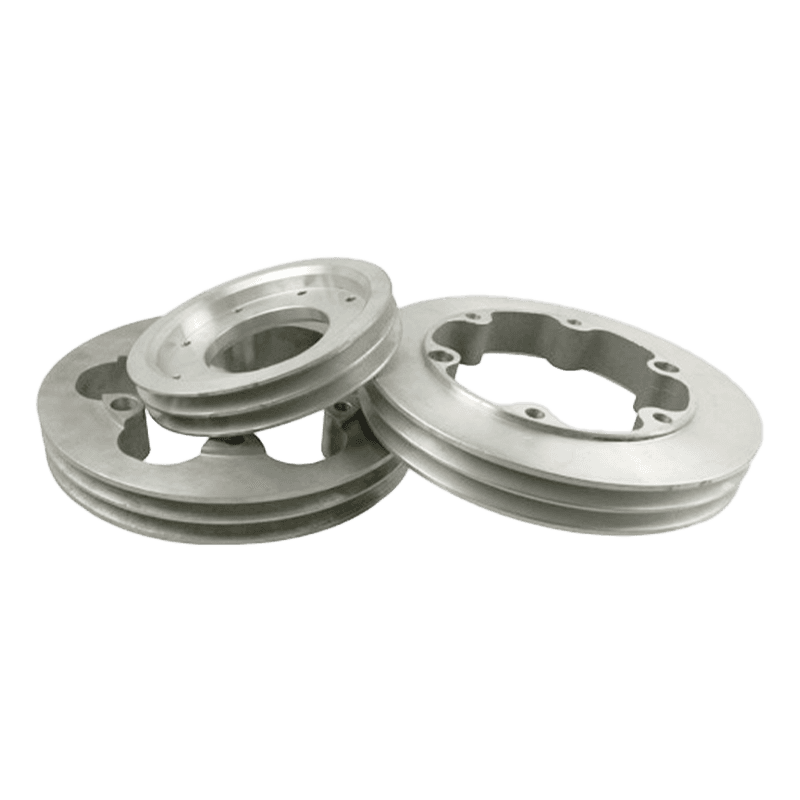

Recyclability: Aluminum is highly recyclable, and the die casting process can incorporate recycled aluminum scrap without significantly affecting the quality of the final product. This reduces the demand for primary aluminum production, which is energy-intensive.

Emissions and Byproducts: Die casting can produce fewer harmful emissions and byproducts than some other methods, particularly if modern, efficient melting technologies are used. However, the process still requires careful management to mitigate any potential environmental impacts, such as fume generation and waste disposal.

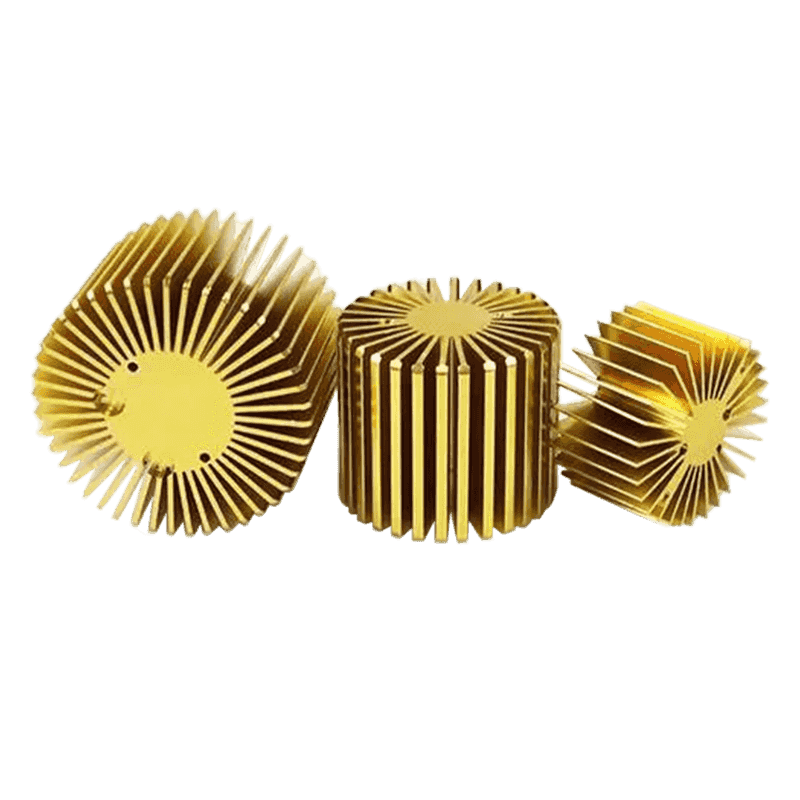

Surface Finish and Coatings: The smooth surface finish achieved in aluminum die casting can reduce the need for additional surface treatments, which may involve chemicals and solvents that have environmental implications. However, if additional coatings are needed, they should be considered in the overall environmental impact assessment.

Life Cycle Assessment (LCA): Studies comparing the environmental impact of various casting methods often show that aluminum die casting has a favorable profile in terms of life cycle emissions and resource consumption, particularly when considering the entire life cycle of the product, from material extraction to end-of-life recycling.

Regulatory Compliance: The die casting industry is increasingly focusing on compliance with environmental regulations and standards, which can drive improvements in processes and reduce environmental impacts across the board.

Are You Interested In Our Products

Leave your name and email address to get our prices and details immediately.

English

English 中文简体

中文简体 Deutsch

Deutsch русский

русский