The importance of material selection for aluminum die-casting products

31-07-2024Material selection for aluminum die-casting products is a critical part of the manufacturing process. Different aluminum alloy materials have their own unique physical, chemical and mechanical properties, which directly affect the quality and performance of the final product.

The following are several key aspects that illustrate the importance of material selection in aluminum die-casting products:

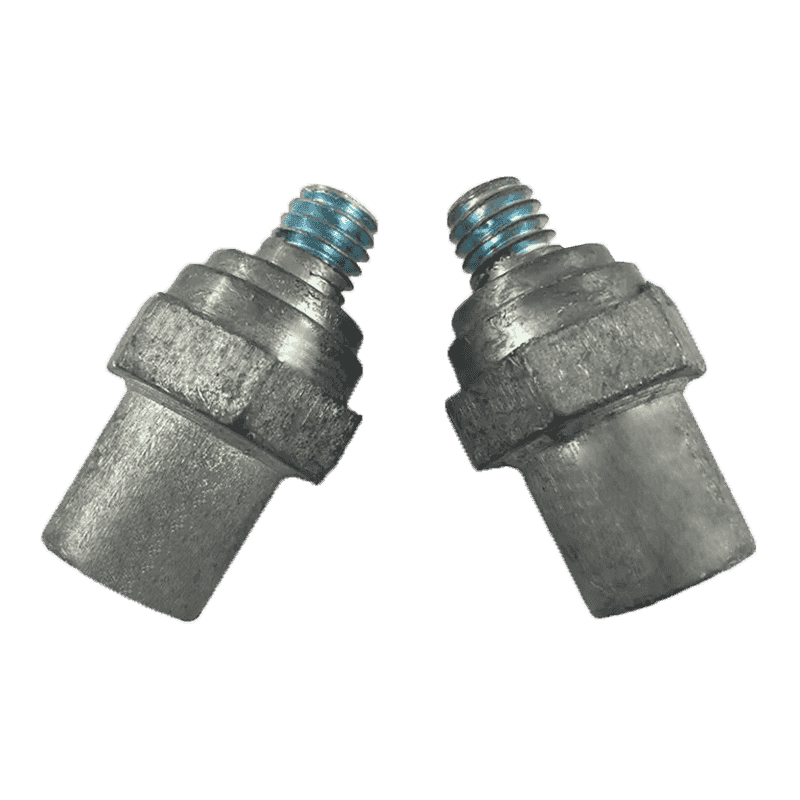

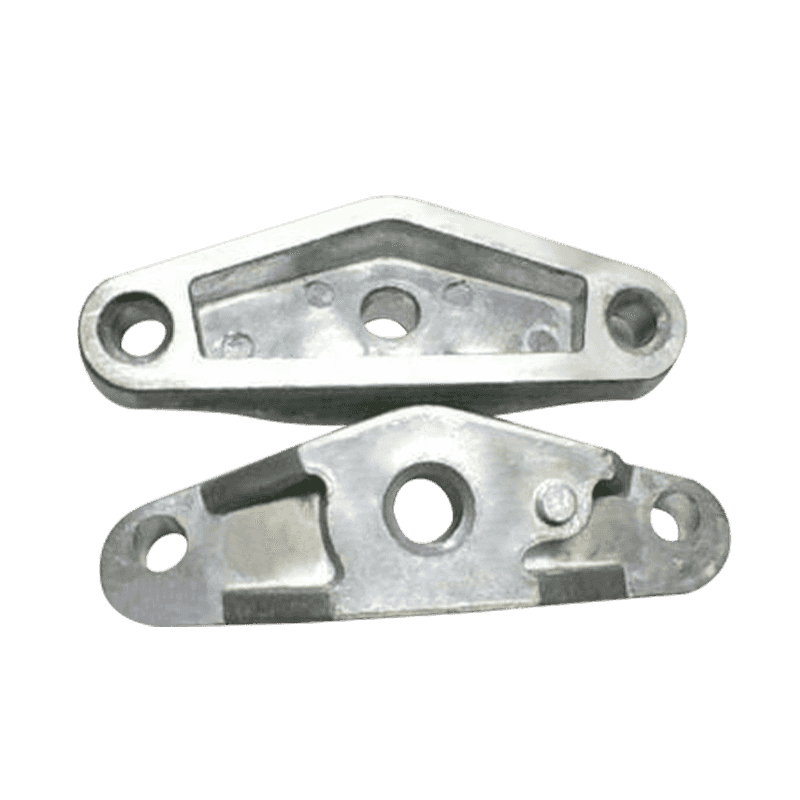

Mechanical properties and strength requirements

Aluminum alloys can improve their mechanical properties and strength through appropriate heat treatment and alloying during the die-casting process. Different application areas have different strength requirements for products, such as automotive engine parts and aerospace components that require high strength and wear resistance, while electronic equipment housings require lightweight design and excellent surface treatment characteristics. The correct selection of aluminum alloy materials can ensure that the product maintains stable performance under various stress and environmental conditions.

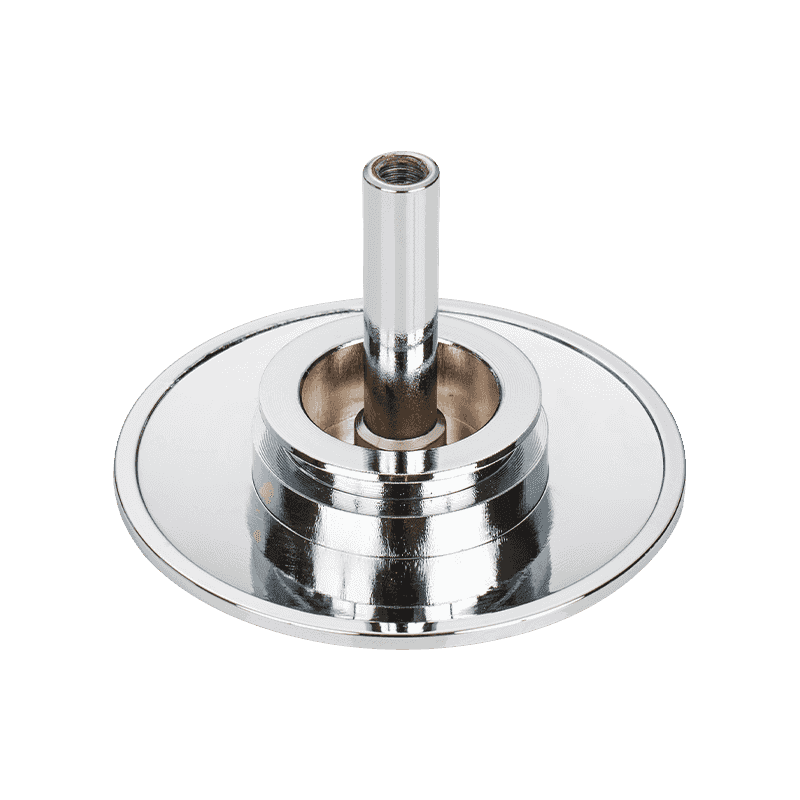

Corrosion resistance and environmental adaptability

Aluminum alloys are widely used in multiple application areas due to their excellent corrosion resistance. Specific alloy formulations and surface treatments can enhance their oxidation and corrosion resistance, allowing them to maintain long-term stability in humid, high temperature or chemical environments. Choosing the right aluminum alloy material can effectively extend the service life of the product and reduce maintenance costs.

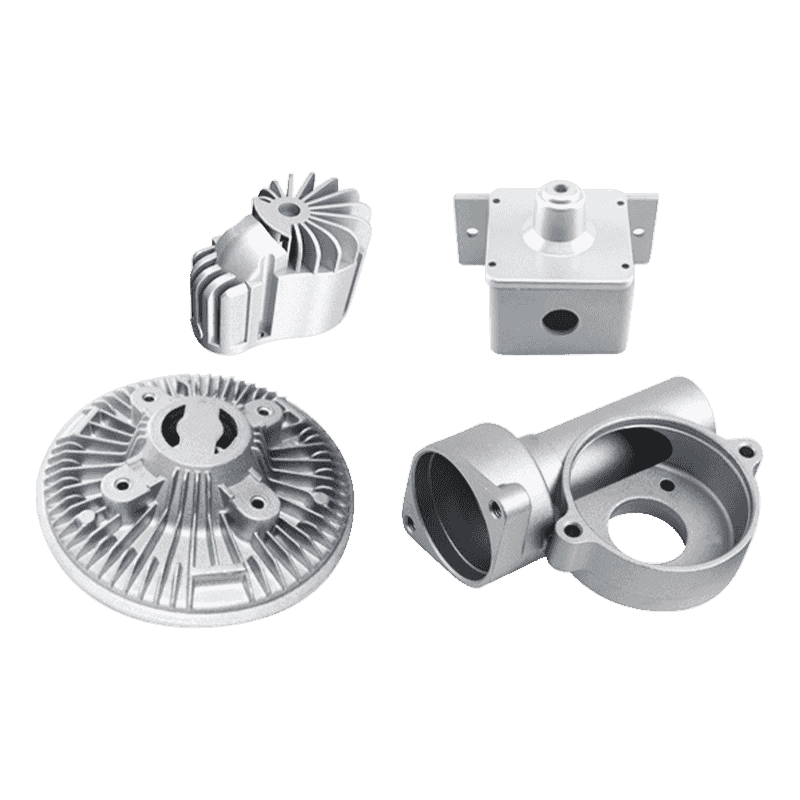

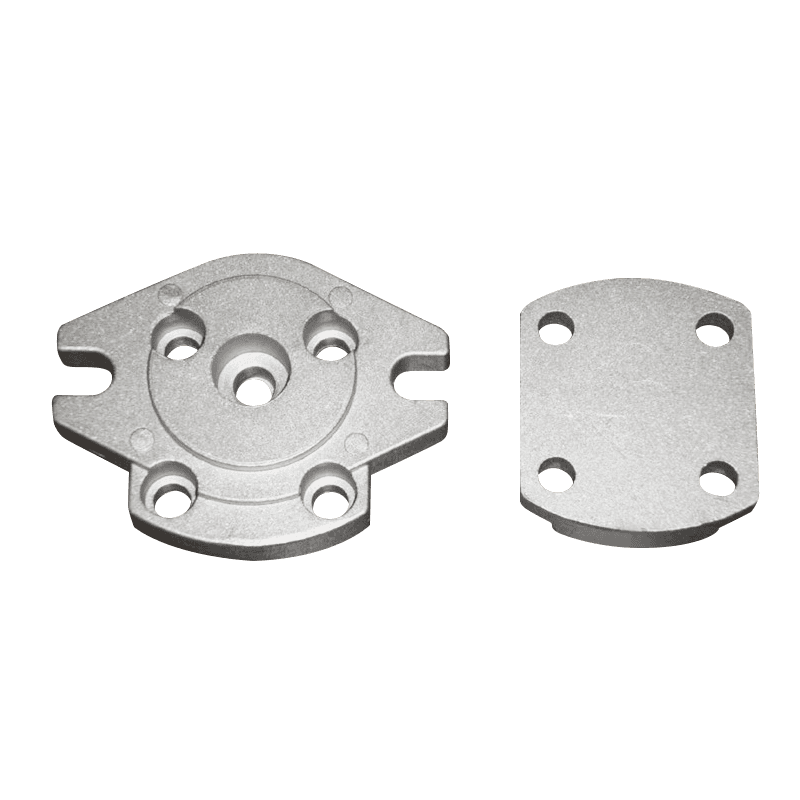

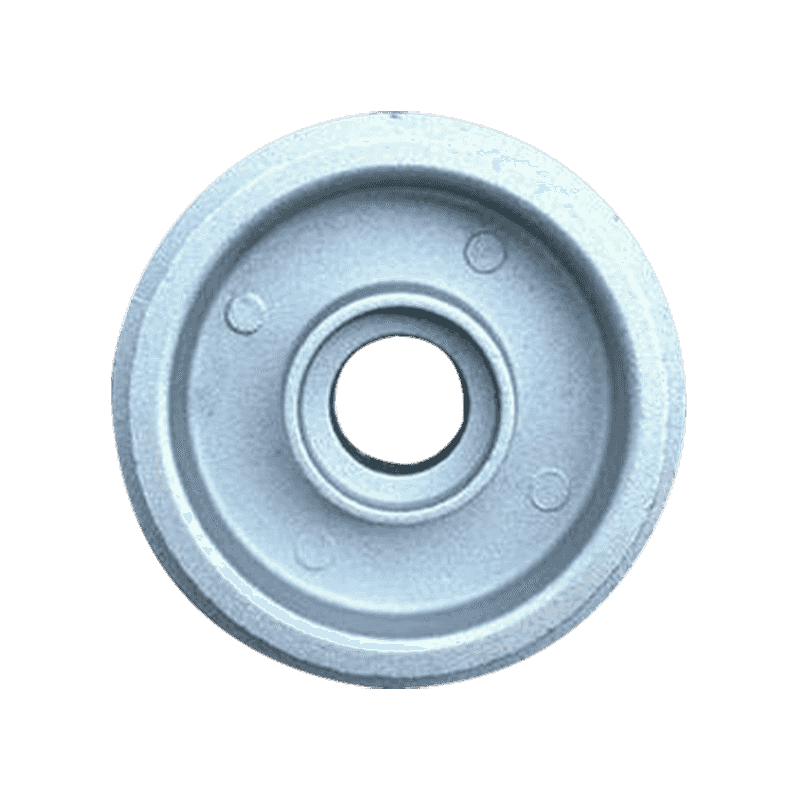

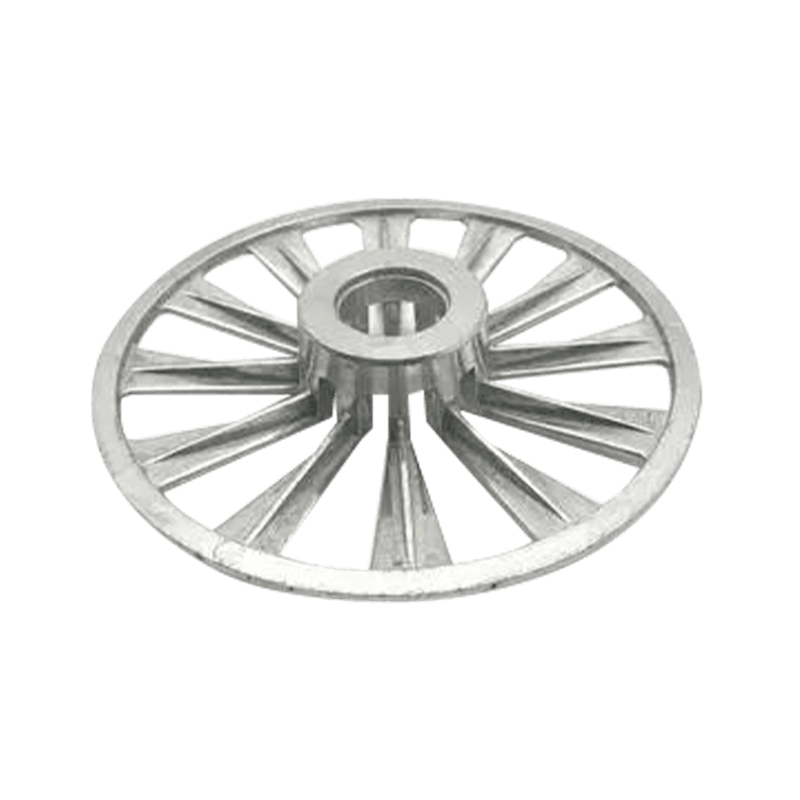

Processing performance and complex geometry

Aluminum die casting can achieve the manufacturing of parts with complex geometry and precise details, and choosing the right aluminum alloy material is the key to achieving this goal. Excellent fluidity and casting performance can ensure that the material is evenly distributed during the mold filling process, avoiding bubbles and inclusions, thereby improving the quality and surface smoothness of the product. When facing the customized design needs of customers, the correct selection of materials can effectively reduce manufacturing costs and processing cycles, and improve production efficiency and product competitiveness.

Are You Interested In Our Products

Leave your name and email address to get our prices and details immediately.

English

English 中文简体

中文简体 Deutsch

Deutsch русский

русский