Unique light and shadow effects of zinc alloy die-cast lighting fittings

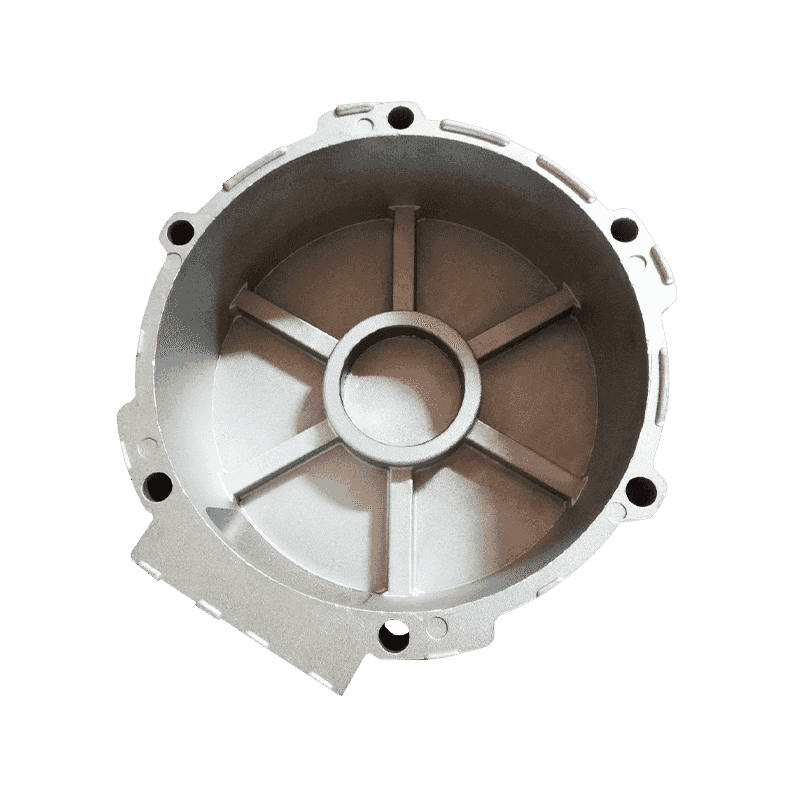

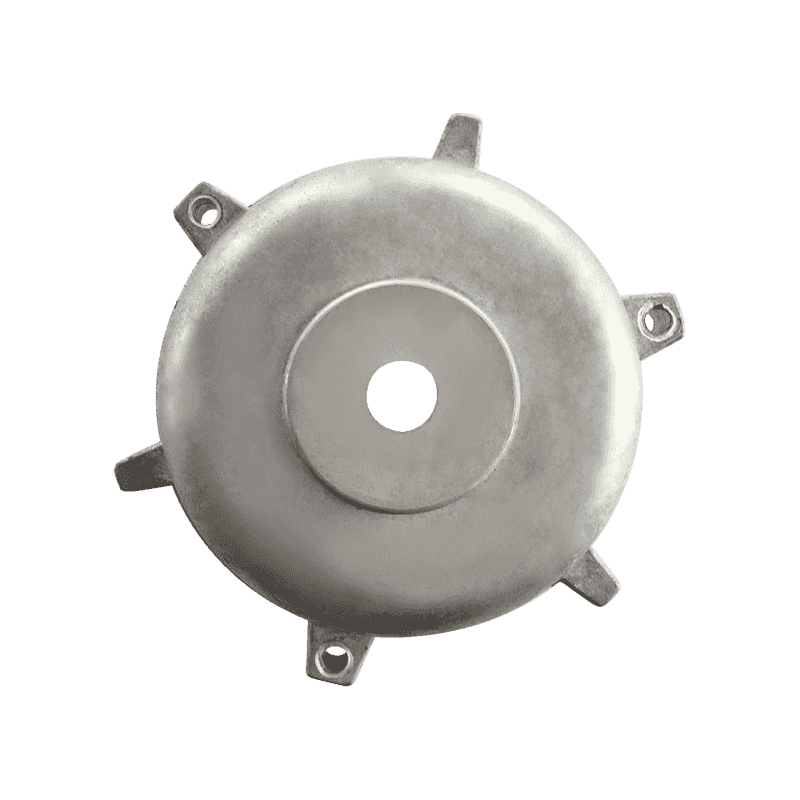

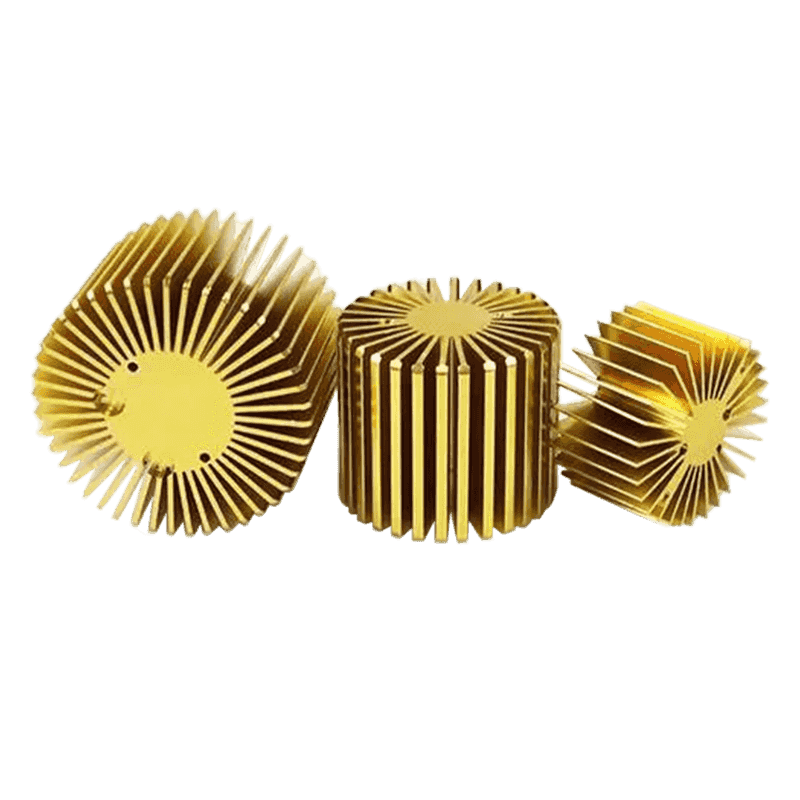

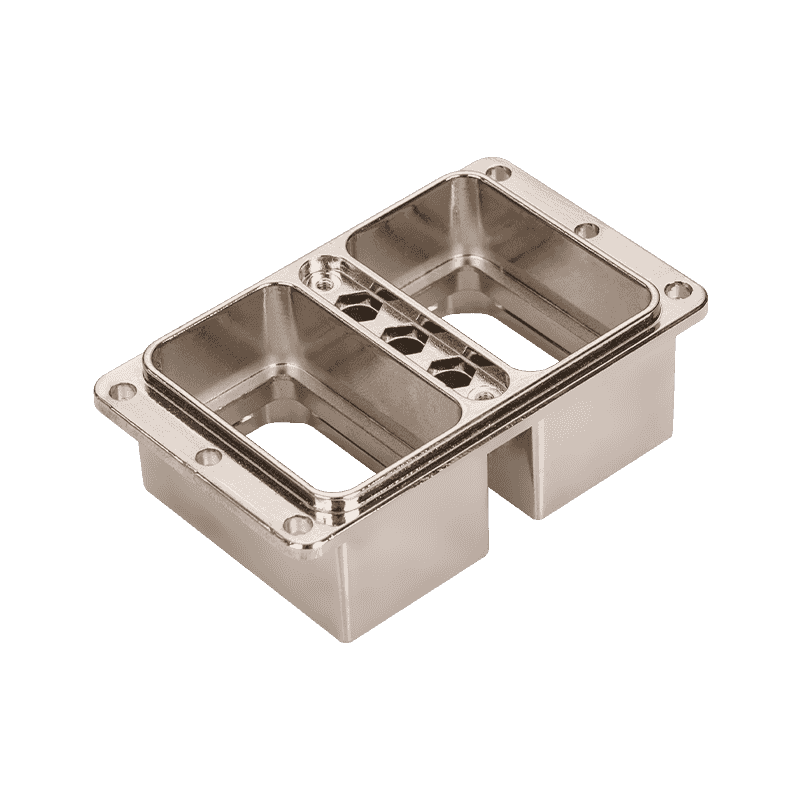

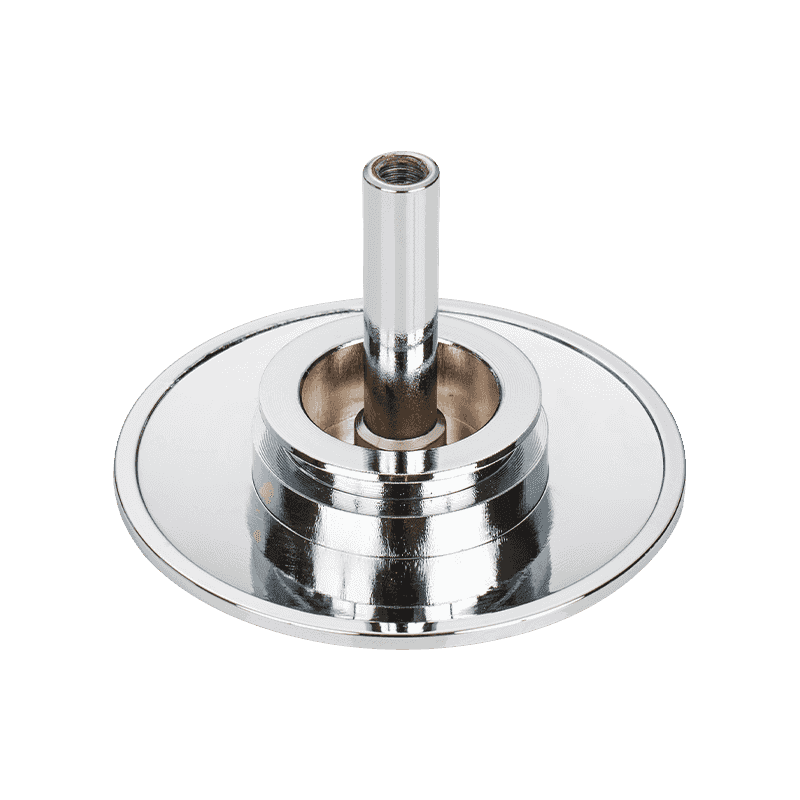

15-10-2024The surface of zinc alloy die-cast parts is smooth and has good reflective ability, which makes the application of zinc alloy die-cast lighting fittings in lamps effectively enhance the reflection and refraction effects of light. Designers can optimize the path of light by precisely controlling the design and surface treatment of the mold, thereby achieving unexpected visual effects. For example, a reflector with a smooth surface can evenly distribute the light emitted by the light source to create a soft lighting atmosphere, while a textured surface can break up the straight beam of light to form dynamic light and shadow.

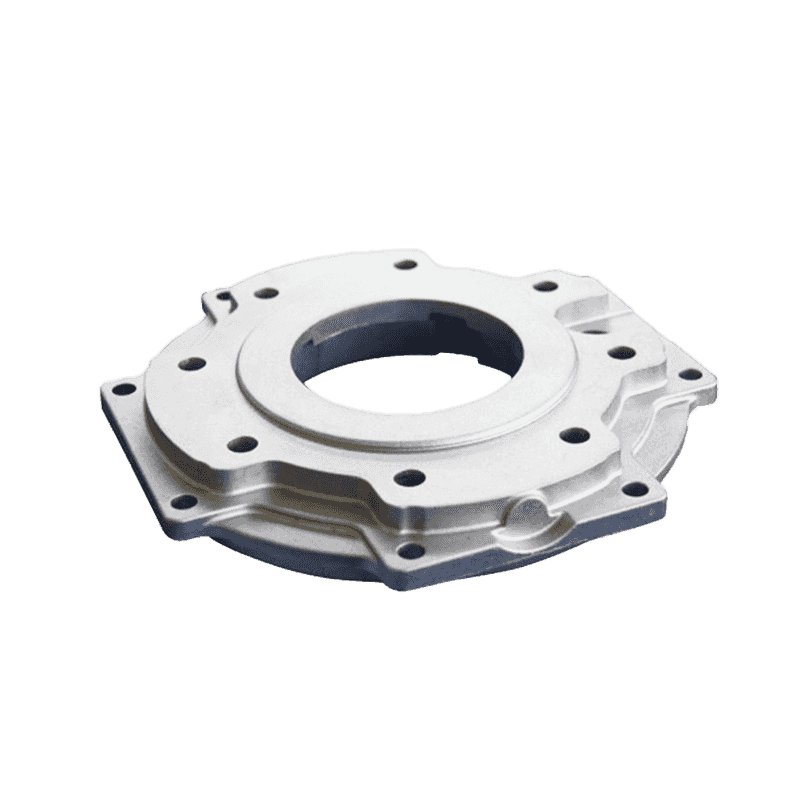

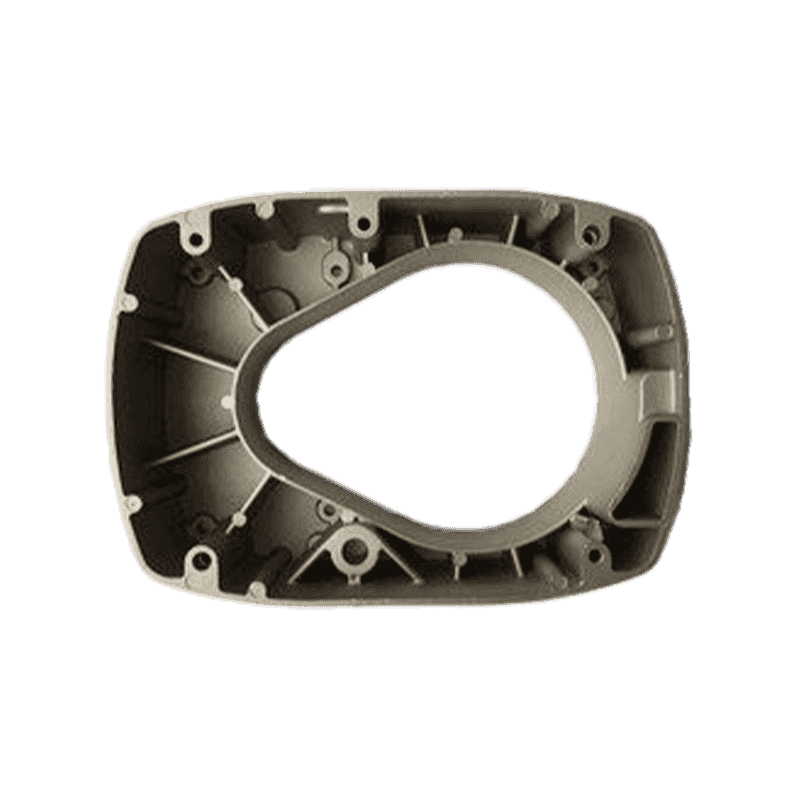

The surface treatment technology of zinc alloy provides a wide range of design space for lighting fittings. Common surface treatment methods such as electroplating, spraying and anodizing not only improve the corrosion resistance of zinc alloy, but also change its visual characteristics. For example, electroplating can give the fittings a glossy feel, making them sparkle in the light, while matte treatment can scatter light and soften the lighting effect of the lamp. Using engraving, polishing and other techniques to create unique patterns and textures on the surface of zinc alloy can achieve complex light and shadow effects and enhance the artistry and design sense of the product.

Zinc alloy die-casting technology can achieve complex shapes, which provides more possibilities for the light and shadow effects of lighting accessories. Designers can guide the direction of light through the shape of the lamp, making the interaction between light and shadow more layered. For example, using curved or layered designs can produce staggered light and shadow, creating a rich sense of space and visual dynamics. The combination of embedded light sources and translucent materials can also allow light to pass through the edges of the accessories, forming a soft halo effect, enhancing the atmosphere of the entire lamp.

Are You Interested In Our Products

Leave your name and email address to get our prices and details immediately.

English

English 中文简体

中文简体 Deutsch

Deutsch русский

русский