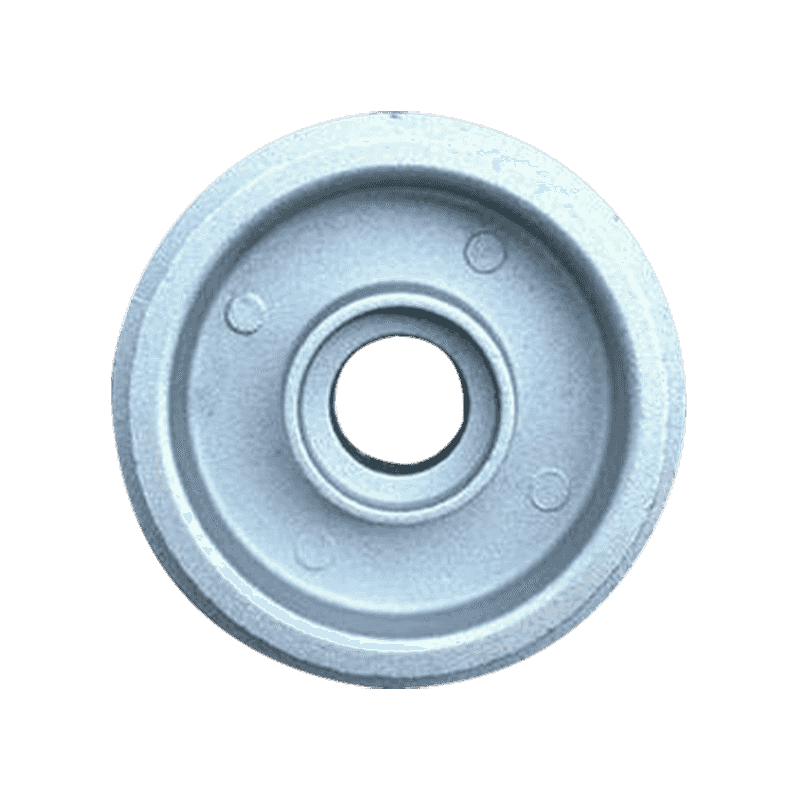

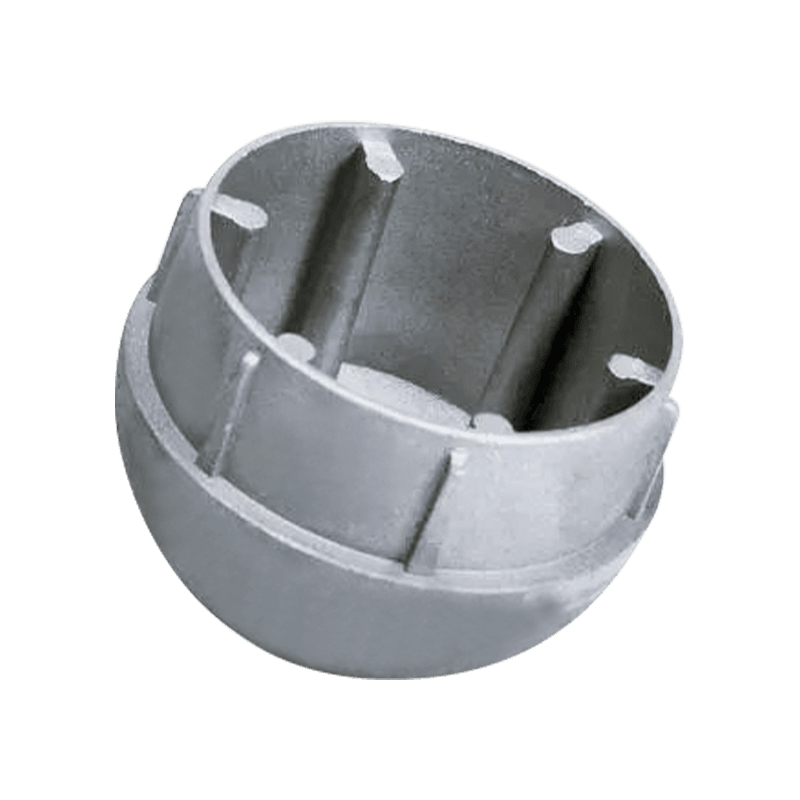

Zinc Die Casting’s technological innovation and future development prospects

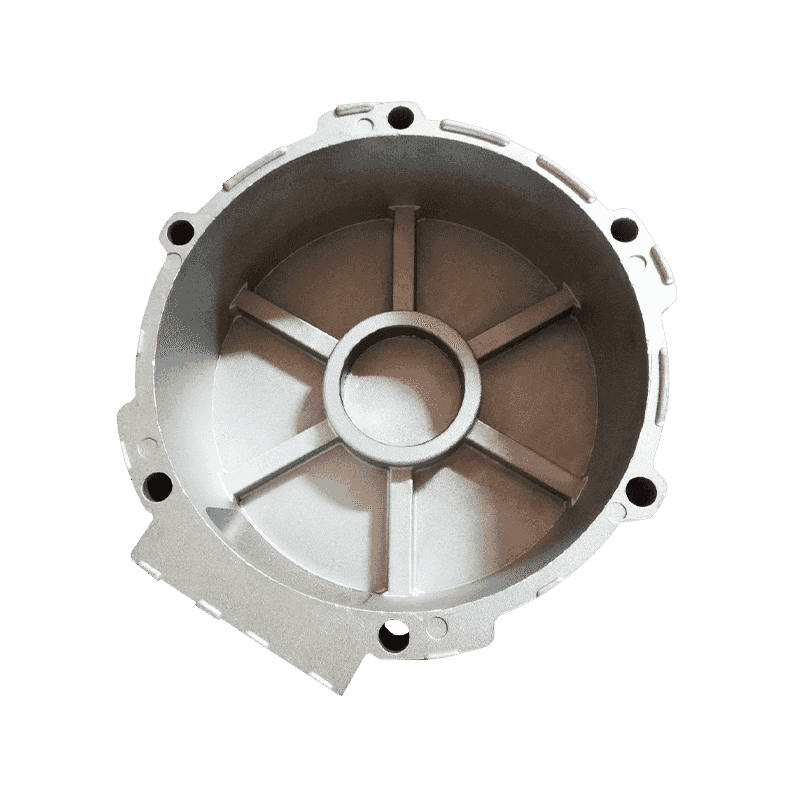

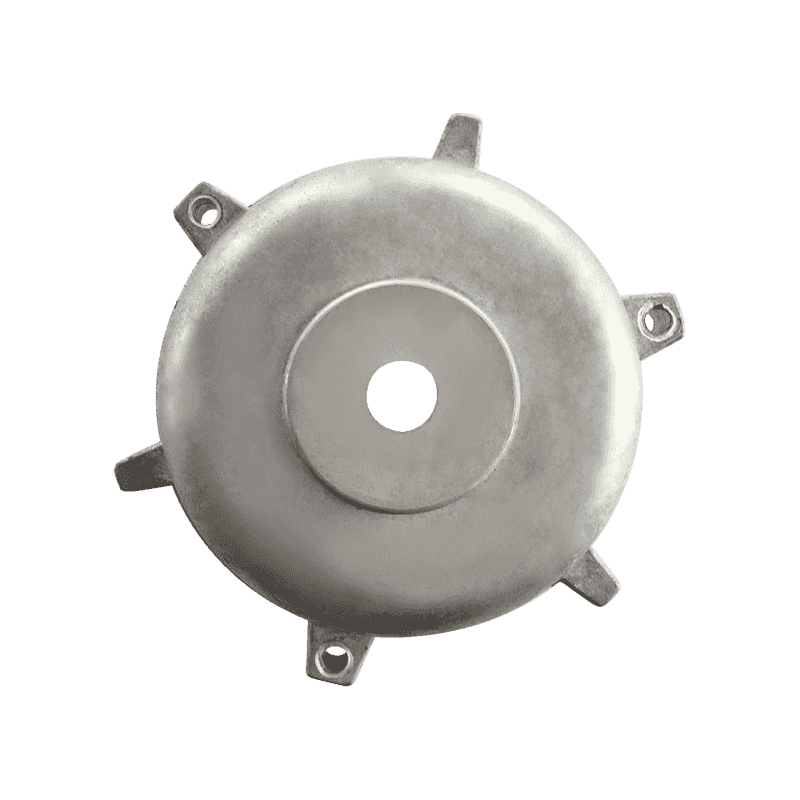

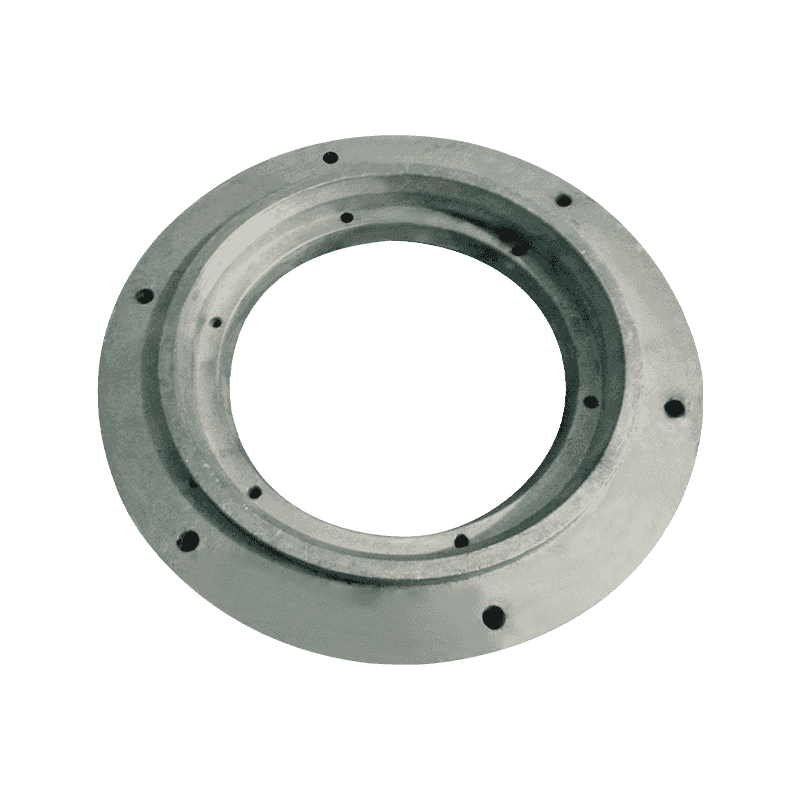

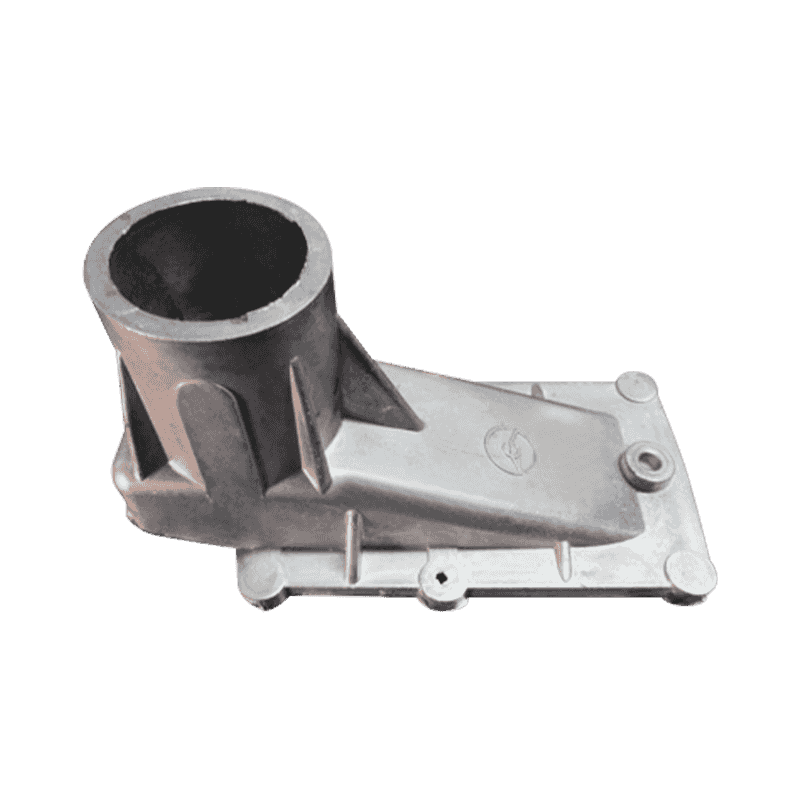

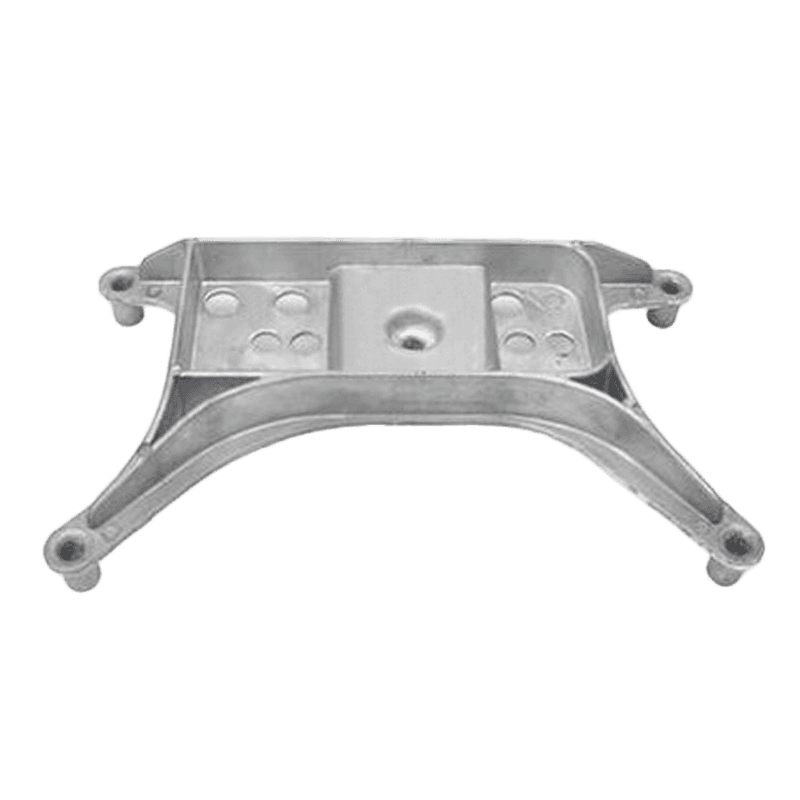

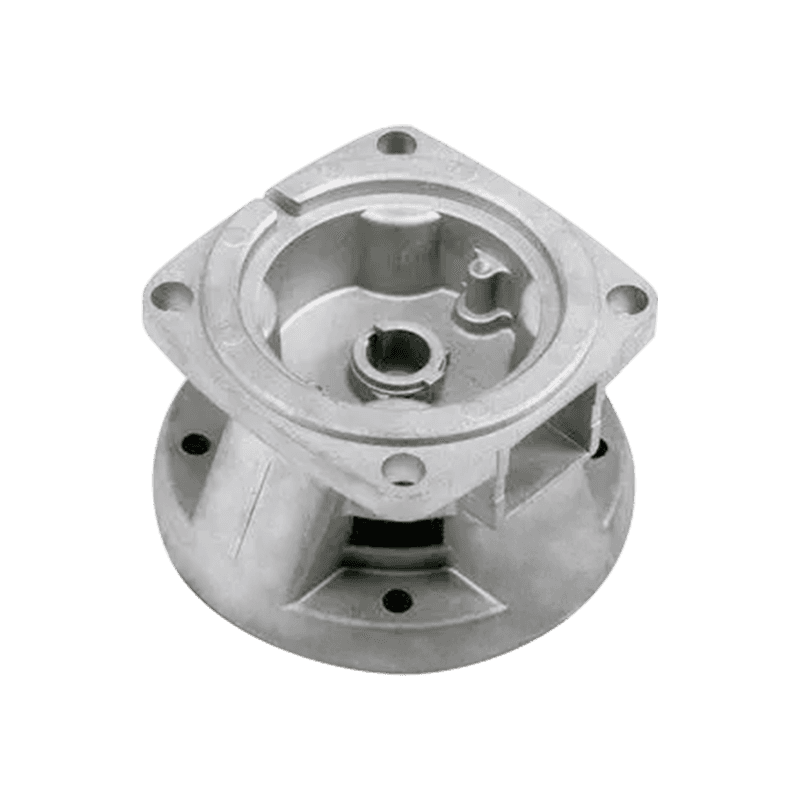

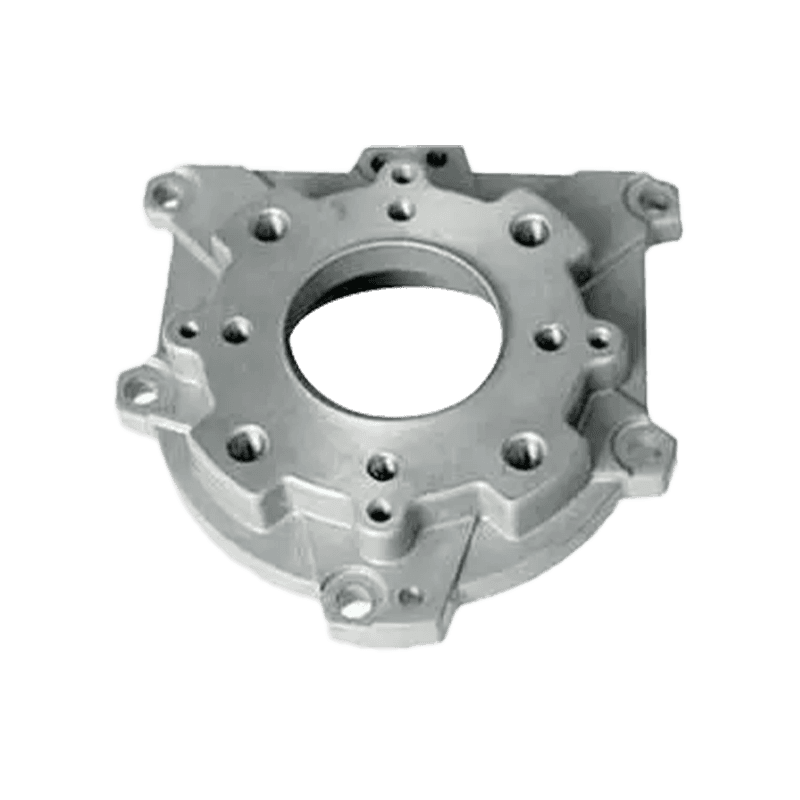

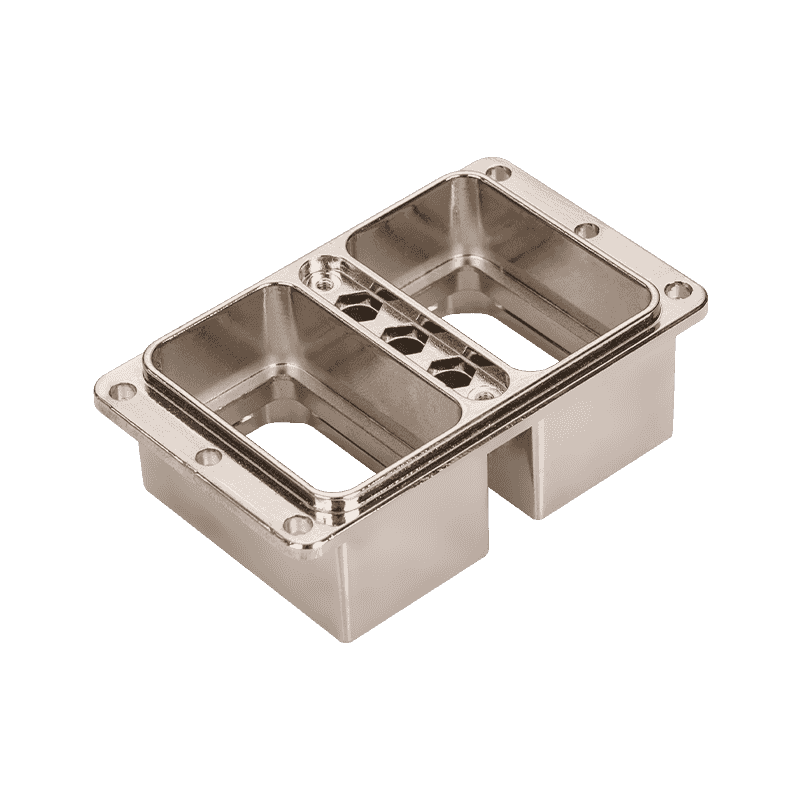

14-08-2024As an important metal processing technology in the manufacturing industry, Zinc Die Casting is not only famous for its efficient production capacity and precise manufacturing process, but also goes further and further on the road of continuous innovation and technological progress.

Continuous optimization of manufacturing processes

With the continuous advancement of manufacturing technology, the manufacturing process of zinc die casting is also continuously optimized. The application of advanced mold design and CAD/CAM technology makes the design and production of parts more accurate and efficient. Through simulation and virtual reality technology, manufacturers can conduct detailed analysis and optimization before production, reducing production cycle and improving product quality.

Applications of new materials and alloys

With the development of materials science, new zinc alloys are being introduced into the production of zinc die casting. These new materials not only provide better mechanical properties and corrosion resistance, but also can meet the needs of increasingly complex and demanding designs. At the same time, manufacturers can customize material properties to meet the needs of different industries and application fields.

Automation and intelligent manufacturing

With the promotion of Industry 4.0, automation and intelligent manufacturing technology are gradually being applied to zinc die-casting production lines. Automation systems can achieve a high degree of integration and automatic control of the production process, improving production efficiency and product consistency. Smart manufacturing technologies such as the Internet of Things (IoT) and big data analysis provide manufacturers with real-time monitoring and predictive maintenance capabilities, further improving the intelligence level of production.

Sustainable development strategies and practices

Facing the global trend of sustainable development, zinc die-casting manufacturers actively respond to environmental protection requirements and continue to promote their own sustainable development strategies through measures such as reducing energy consumption, optimizing waste processing, and improving material utilization. The introduction of environmental certification and green production standards has given zinc die-casting products higher credibility in the market.

New markets and application expansion

With changes in global market demand and the rise of emerging industries, zinc die-casting technology has gradually expanded to more application fields. For example, high-tech fields such as aerospace, medical equipment and new energy technology have increasing requirements for high precision, lightweight and durability, and zinc die-casting technology is able to provide innovative solutions for these fields.

Are You Interested In Our Products

Leave your name and email address to get our prices and details immediately.

English

English 中文简体

中文简体 Deutsch

Deutsch русский

русский