Advantages and Disadvantages of Aluminum Extrusion and Machining Chemical Plating

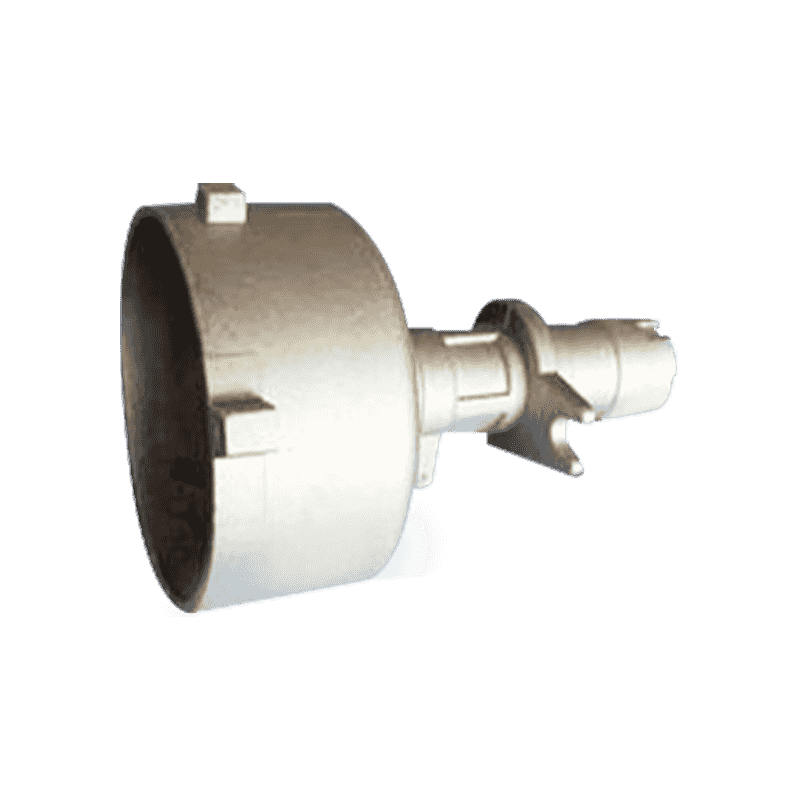

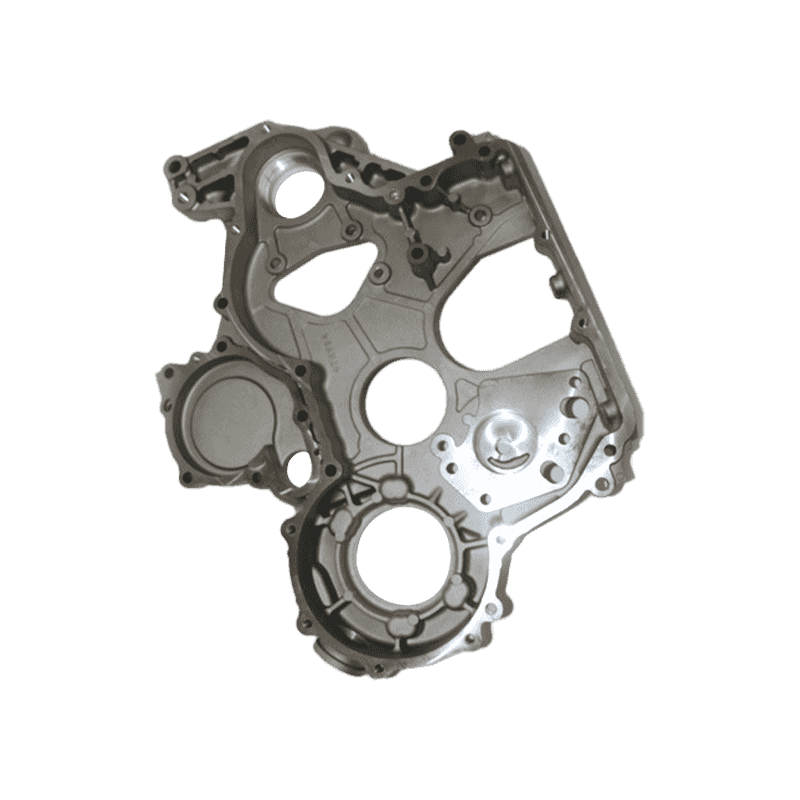

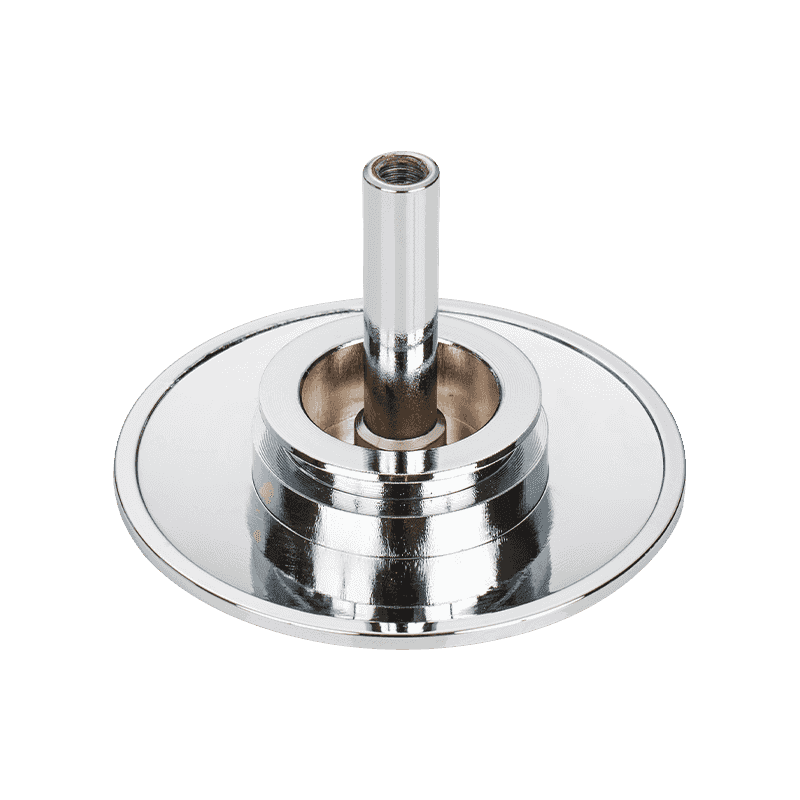

04-09-2024A major advantage of aluminum extrusion and machining chemical plating is the ability to form a uniform metal coating on complex aluminum parts. This is because the chemical plating process does not rely on electric current, and the coating is deposited uniformly on every surface of the aluminum material, including complex geometries and tiny details, through chemical reactions. This makes chemical plating particularly suitable for the surface treatment of precision parts, such as electronic components and high-precision mechanical parts.

High Adhesion: The metal layer generated by chemical plating usually has good adhesion and can effectively bond to the aluminum substrate. This strong adhesion coating is not easy to peel or fall off, which enhances the durability and reliability of aluminum parts. This feature is particularly important under high load and harsh environmental conditions.

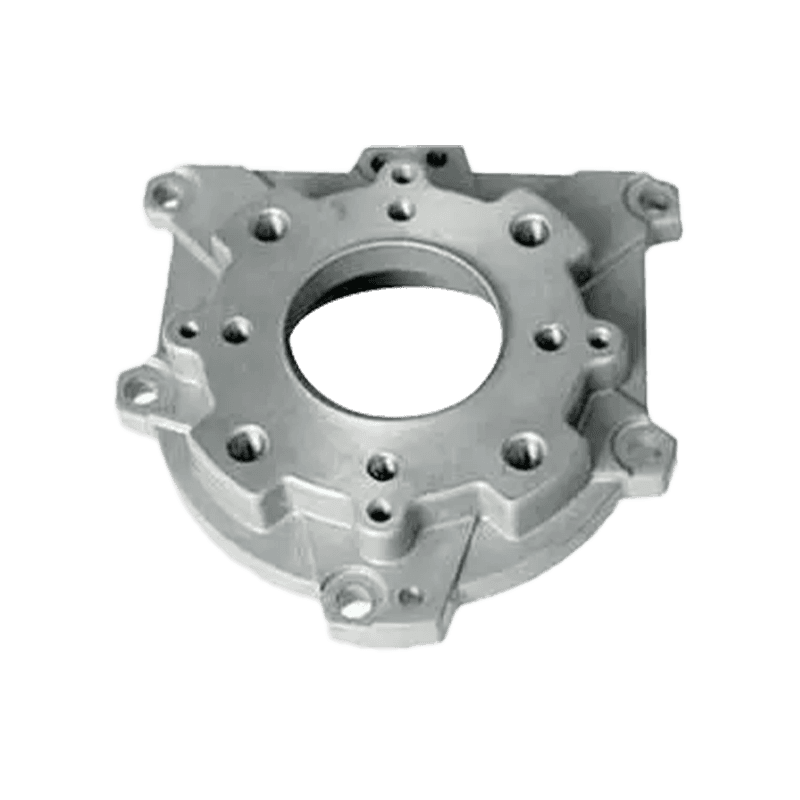

Good Corrosion Resistance: Chemical nickel plating provides good corrosion resistance, allowing aluminum to remain stable under various chemical and environmental conditions.

Improved Wear Resistance: Aluminum extrusion and machining can improve the wear resistance of aluminum through chemical plating, especially in applications requiring high wear resistance.

Disadvantages

Higher Cost: Compared with other surface treatment methods, the aluminum extrusion and machining chemical plating process is more expensive. This is because the electroless plating process requires the use of high-purity chemicals, complex equipment, and strict process control. Therefore, in applications that require high cost-effectiveness, electroless plating may not be as economical as other treatment methods.

High technical requirements: The electroless plating process has very high requirements for process control, including the temperature, pH value, chemical composition, etc. of the solution. Any slight process deviation may affect the quality and performance of the coating. This means that the operator needs to have a high level of technical skills and experience.

Are You Interested In Our Products

Leave your name and email address to get our prices and details immediately.

English

English 中文简体

中文简体 Deutsch

Deutsch русский

русский