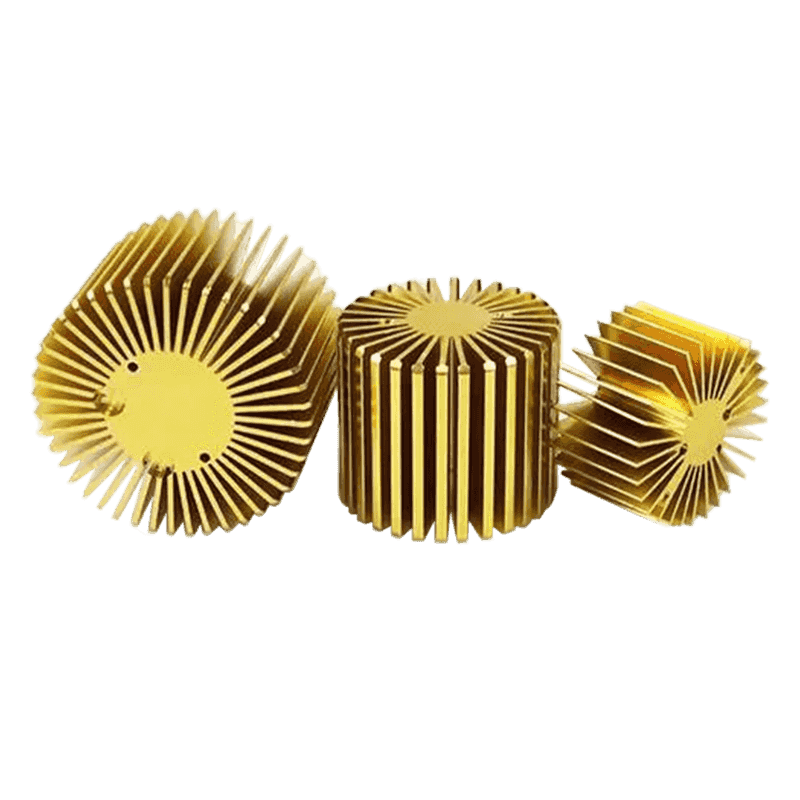

Cooling system in aluminum extrusion and machining

11-09-2024The cooling system plays a vital role in aluminum extrusion and machining. Effective cooling not only affects production efficiency, but is also directly related to product quality, equipment life and energy consumption.

Cooling efficiency

Uniform cooling: The cooling system must ensure that the aluminum is evenly cooled during extrusion and machining to avoid material defects or performance degradation caused by uneven temperature. Uniform cooling can reduce thermal deformation and internal stress, thereby improving the dimensional accuracy and surface quality of the product.

Cooling rate control: Different aluminum alloys have different requirements for cooling rates. When designing the cooling system, it is necessary to adjust the cooling rate according to the specific alloy composition and performance requirements of the aluminum material to optimize the mechanical properties and microstructure of the material.

System structure and layout

Cooling area design: In extruders and processing equipment, the design of the cooling area must be able to effectively cover every part of the aluminum material. Usually, the cooling area includes nozzles, air ducts and coolant circulation systems. Reasonable layout can ensure that the cooling medium can act evenly on the aluminum material.

Flow path optimization: The flow path of the cooling medium should be optimized to avoid uneven cooling. When designing, it is necessary to consider how to distribute the cooling medium evenly to all surfaces of the aluminum through air ducts or pipes.

Cooling medium selection

Air cooling: Cooling with air is a common method, especially for applications requiring lower cooling rates. The air cooling system has a simple structure and is easy to maintain, but the cooling efficiency is low and is greatly affected by ambient temperature and humidity.

Water cooling: Water cooling provides higher cooling efficiency and is suitable for aluminum that needs to be cooled quickly. The water cooling system usually includes a coolant circulation system, a cooling pool, and a heat exchanger. Regular inspection and maintenance are required to prevent scale and contaminants from affecting the cooling effect.

Are You Interested In Our Products

Leave your name and email address to get our prices and details immediately.

English

English 中文简体

中文简体 Deutsch

Deutsch русский

русский