Aluminum Alloy Power Tool Accessories: What are the advantages of using aluminum alloy materials

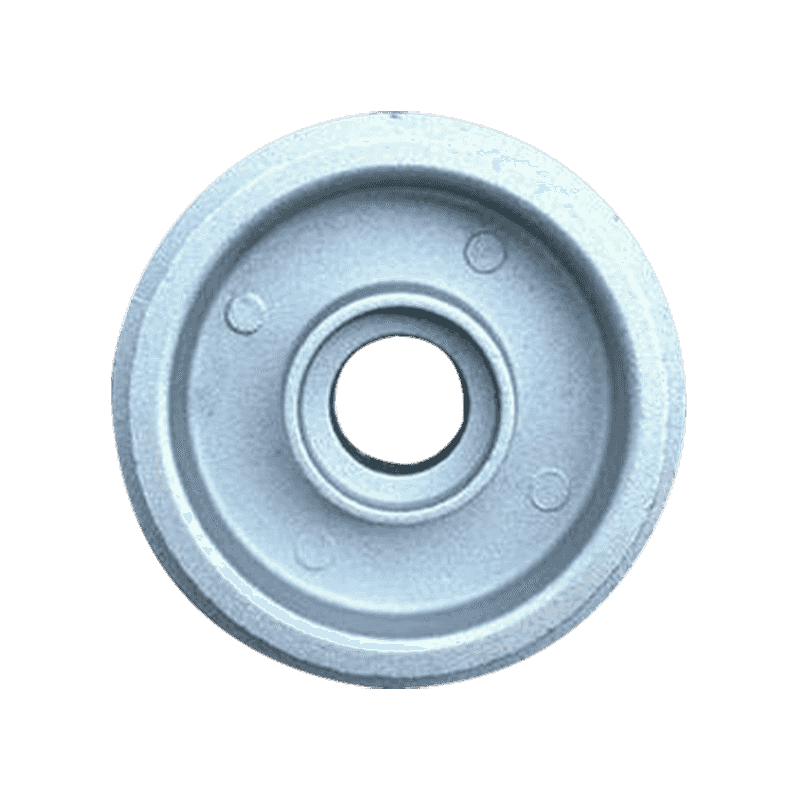

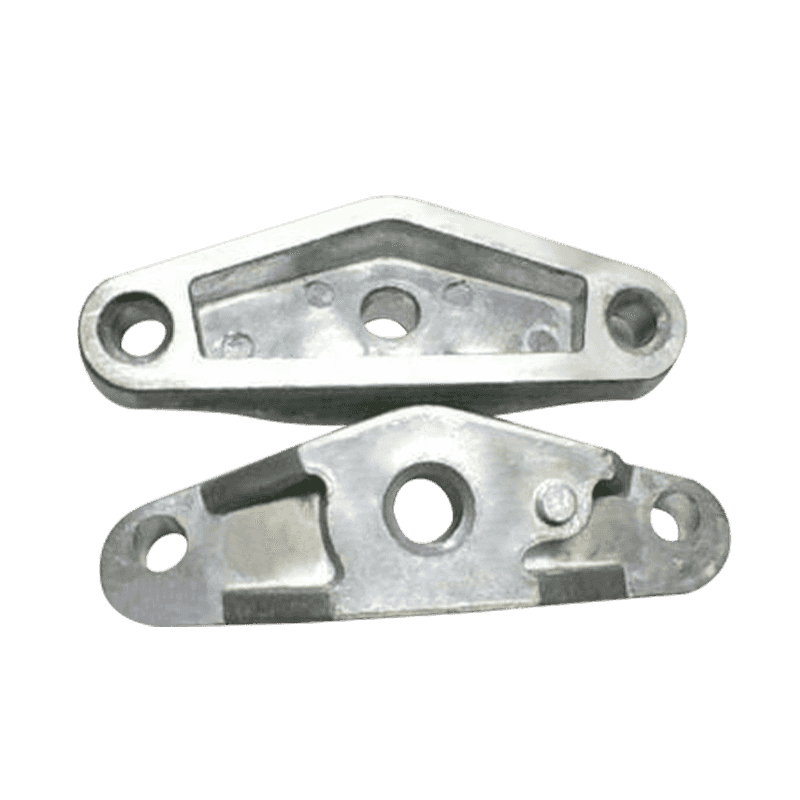

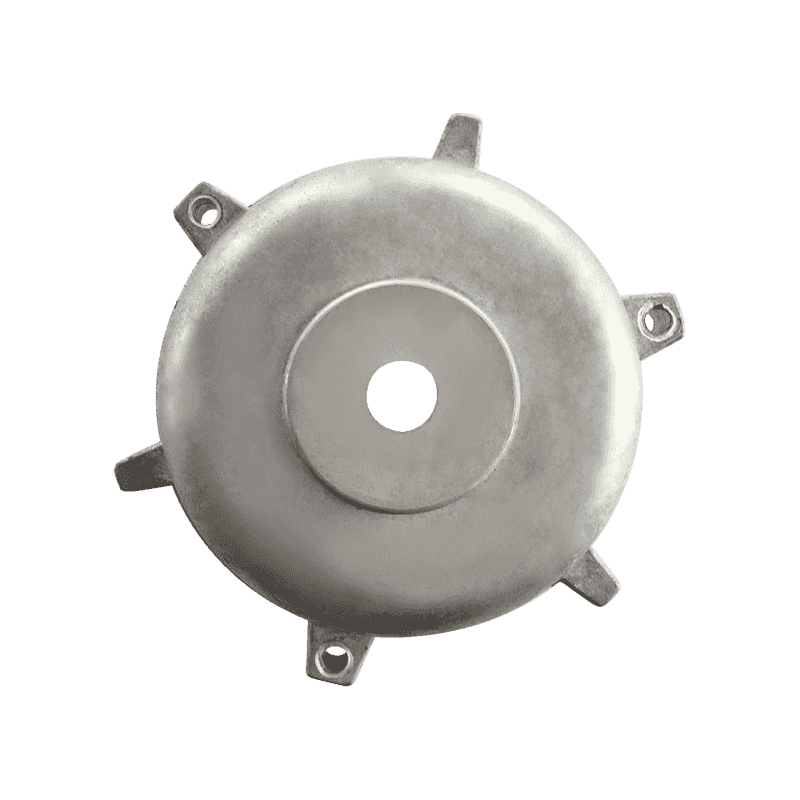

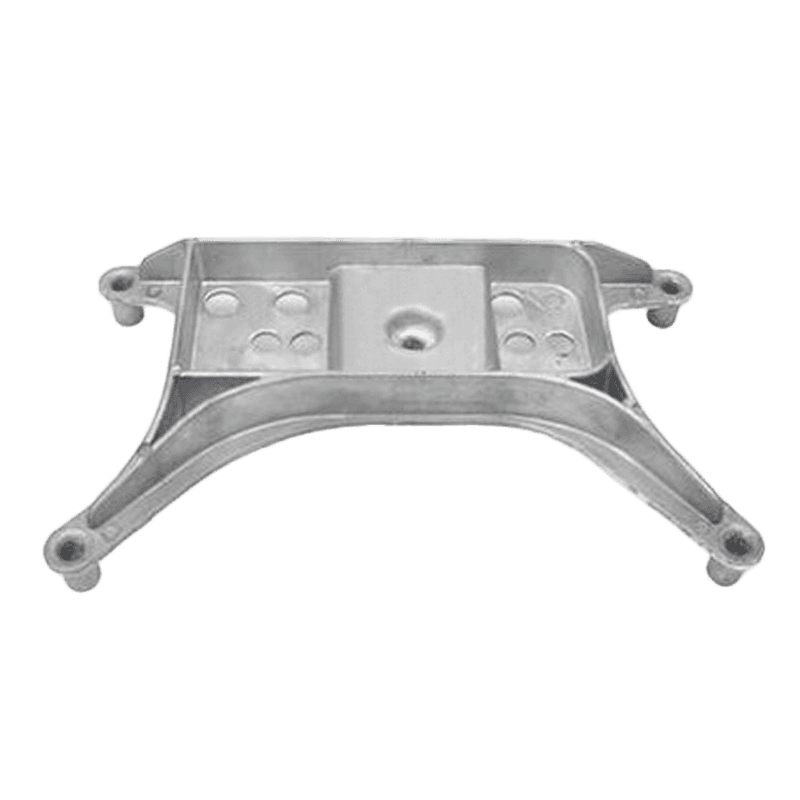

16-07-2024In modern industry and DIY fields, power tools have become indispensable production and maintenance tools. As a lightweight and high-strength metal material, aluminum alloy plays an increasingly important role in the manufacturing of power tool accessories. Aluminum Alloy Power Tool Accessories not only improve the overall performance of the tool, but also bring users a more convenient and efficient use experience. What are the advantages of using aluminum alloy in Aluminum Alloy Power Tool Accessories?

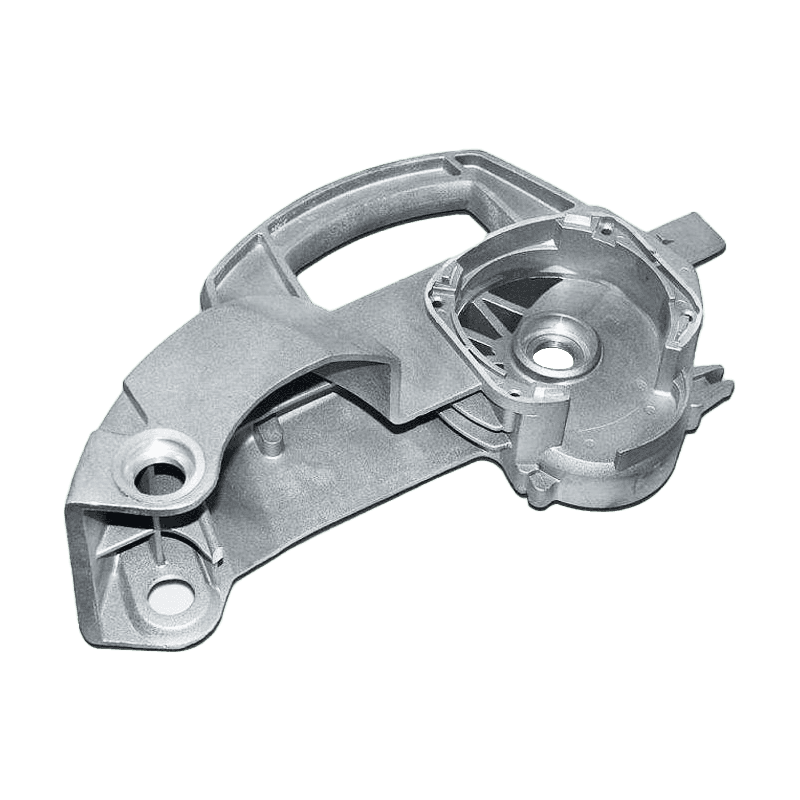

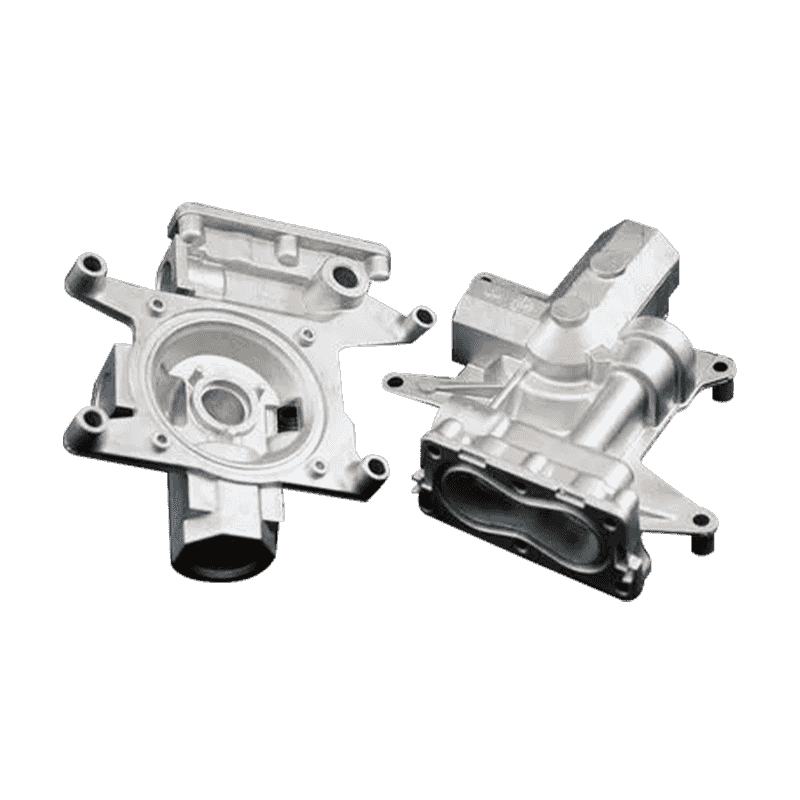

1. Aluminum alloy has the characteristics of low density and light weight. Compared with traditional iron or steel accessories, aluminum alloy accessories can significantly reduce the overall weight of power tools. This feature is very important for tools that require long-term hand-held operation, such as electric drills, angle grinders, electric saws, etc. Power tools using aluminum alloy accessories not only reduce the user's labor intensity and hand fatigue, but also improve work efficiency and safety.

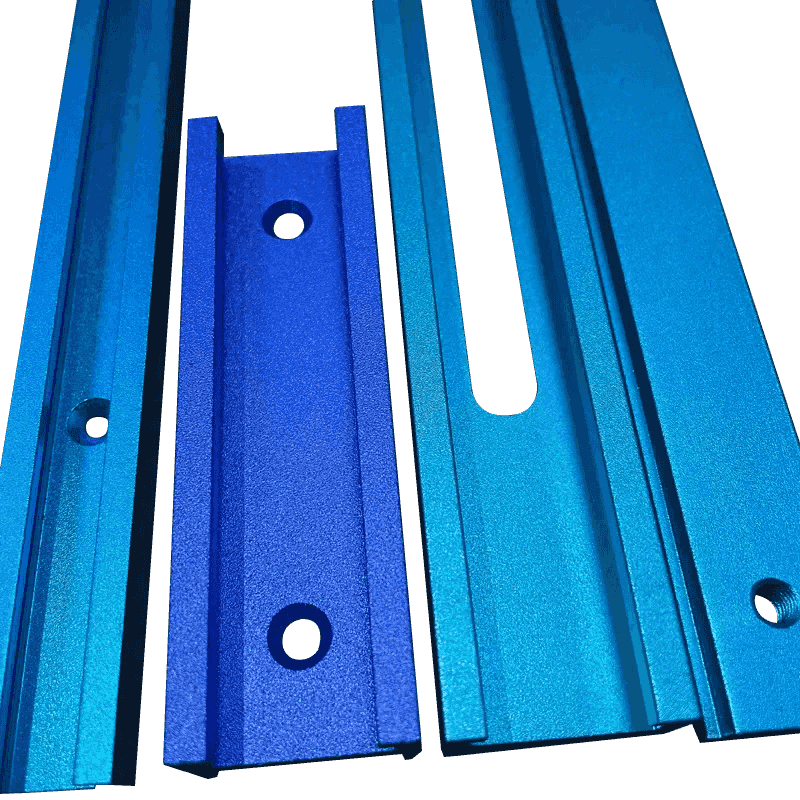

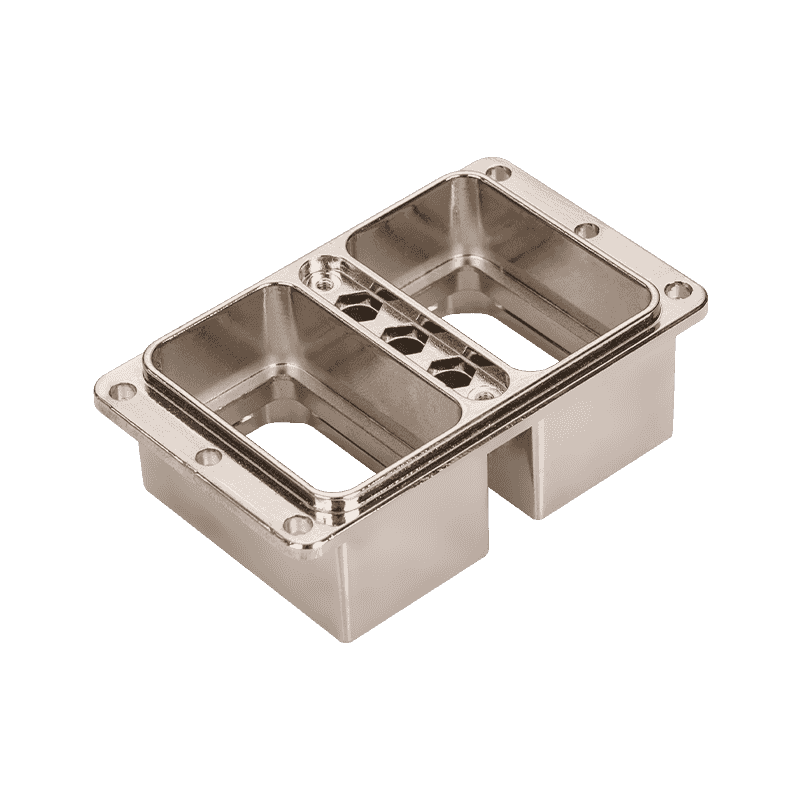

2. A dense oxide film is easily formed on the surface of aluminum alloy. This oxide film has good corrosion resistance and can effectively resist erosion by water, oil, acid and alkali and other substances. In the environment where power tools are used, aluminum alloy accessories can maintain stable performance for a long time and are not prone to rust or corrosion, thus greatly extending the service life of the tool. This is especially important for power tools that often work in wet, harsh environments.

3. Power tools will generate a lot of heat when running at high load for a long time. If the heat cannot be dissipated in time, it will cause damage to the motor. Aluminum alloy materials have good thermal conductivity and heat dissipation, and can quickly transfer the heat generated by the motor. In the air, the normal operating temperature of the motor is maintained. Power tools using aluminum alloy accessories are more stable and reliable during continuous operation, reducing failures and damage caused by overheating.

4. Aluminum alloy materials are easy to process and form. Whether it is casting, forging or cutting, they have good processing effects. This makes aluminum alloy power tool accessories more flexible and diverse in design, and can be customized according to different use needs. Good processing performance also reduces production costs and cycles, and improves production efficiency.

5. Environmentally friendly and sustainable, in line with green development trends

With the global emphasis on environmental protection and sustainable development, aluminum alloy, as a recyclable material, is becoming more and more popular in power tool accessories. After aluminum alloy accessories reach their service life, they can be recycled and reused to reduce resource waste and environmental pollution, which is in line with the concept of green development.

Are You Interested In Our Products

Leave your name and email address to get our prices and details immediately.

English

English 中文简体

中文简体 Deutsch

Deutsch русский

русский