Why Zinc Alloy Power Tool Fittings have high strength and hardness

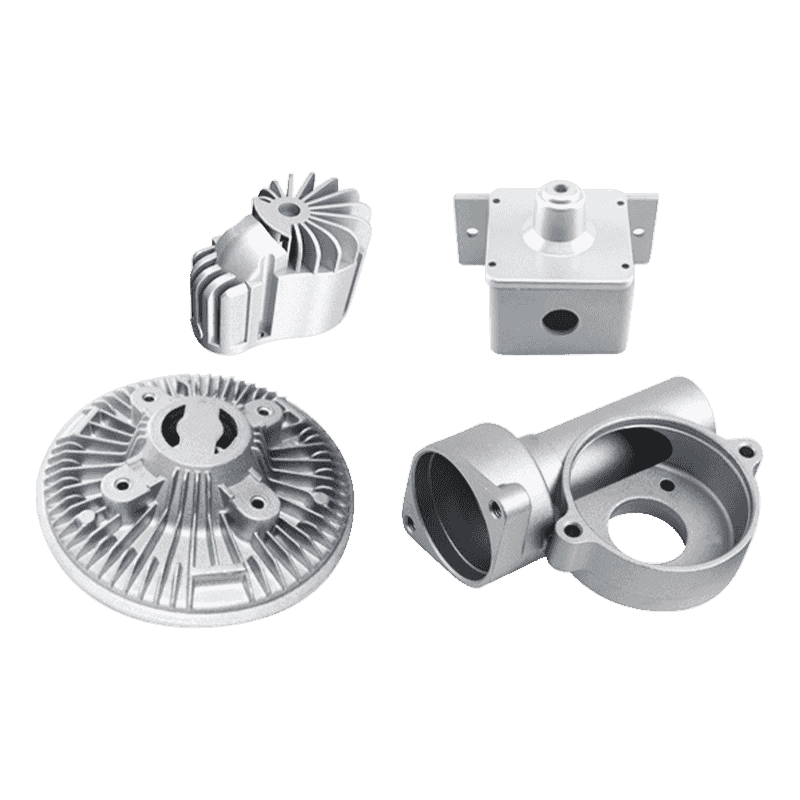

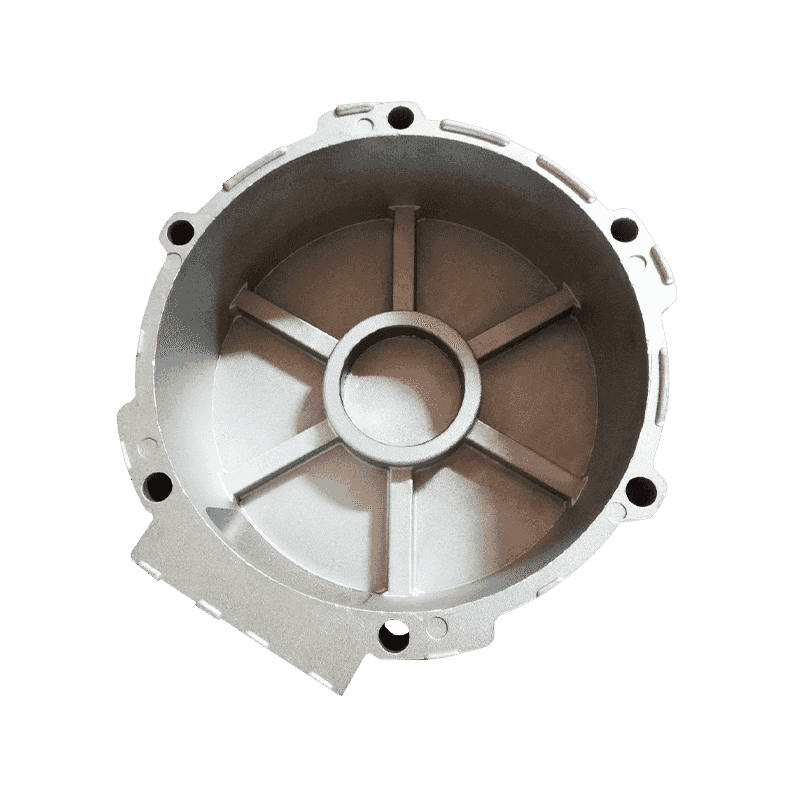

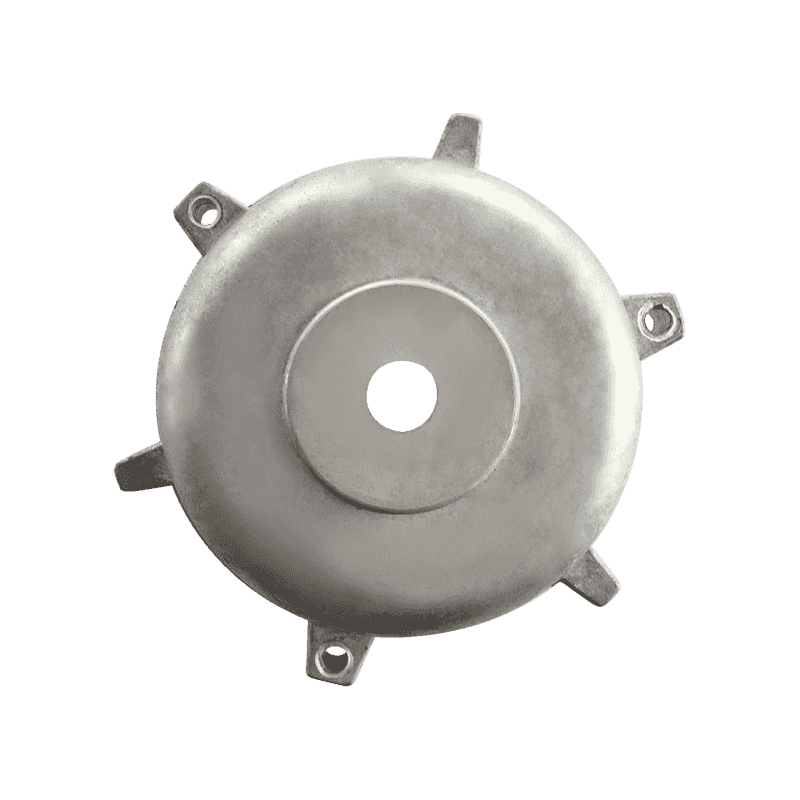

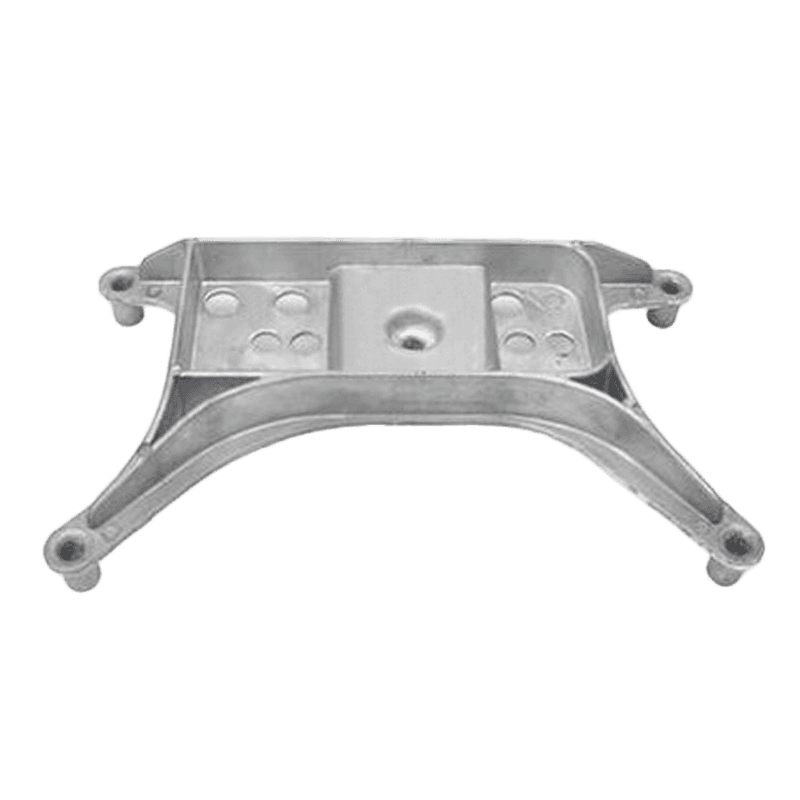

16-07-2024In modern industry and DIY fields, power tools have become an indispensable part. They have greatly improved work efficiency and convenience. Behind these efficient power tools, they are inseparable from the support of a series of high-quality accessories. Zinc Alloy power tool accessories stand out for their high strength and hardness and have become the first choice of many manufacturers and users.

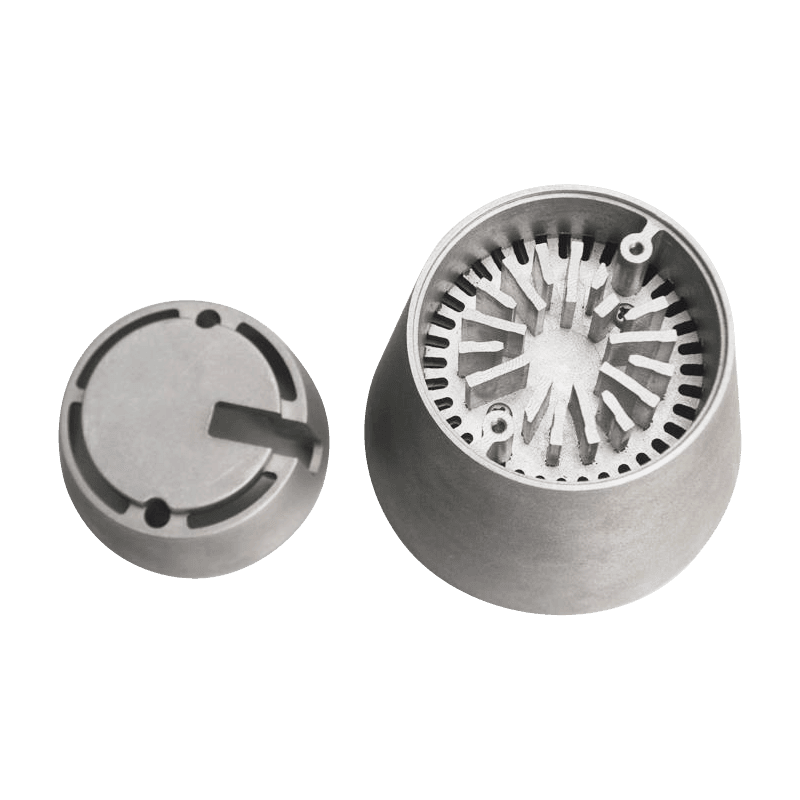

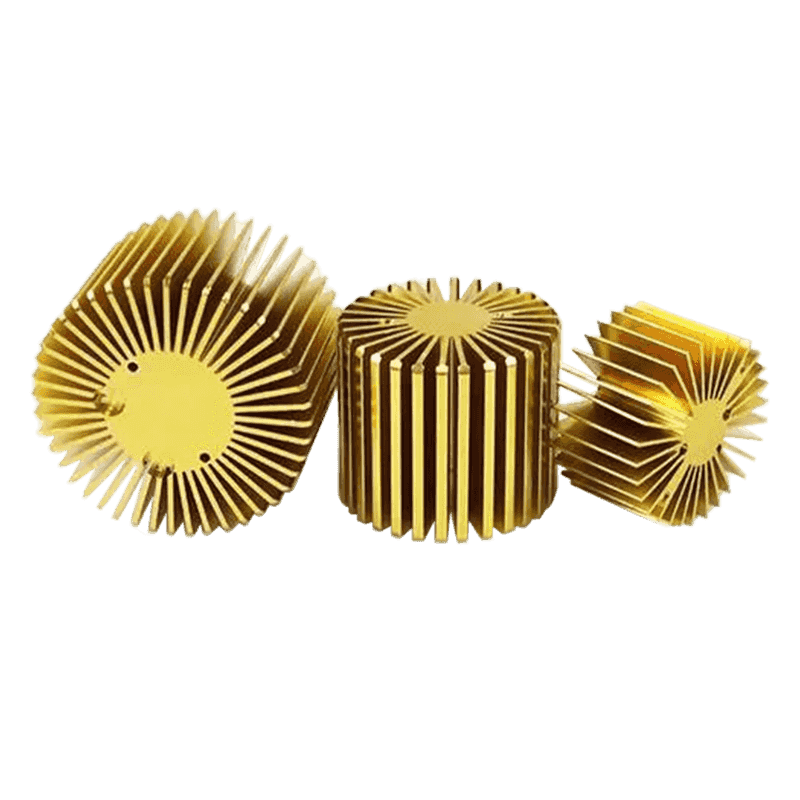

Zinc alloy, as an alloy material composed of zinc and other metal elements, has significantly better physical and chemical properties than pure zinc. Key to this alloy's success in power tool accessories is its exceptional strength and hardness. From the perspective of the composition of the alloy, the zinc alloy forms a complex crystal structure and a dense microstructure by adding other metal elements. This structure allows the alloy to more effectively disperse and resist stress when subjected to external forces, thus improving the Overall strength and stiffness. Compared with pure zinc or other single metal materials, zinc alloys have higher resistance to deformation and wear while maintaining good plasticity and toughness. The alloy undergoes a strict heat treatment process during the manufacturing process. These processes include steps such as smelting, casting, quenching, and tempering, aiming to further improve the internal structure and properties of the alloy. Through heat treatment, the grains of the zinc alloy are refined and the internal stress is eliminated, thereby improving the strength and hardness of the alloy. Heat treatment can also form a dense oxide film on the surface of the alloy to enhance its corrosion resistance. The design and production of zinc alloy power tool accessories also fully consider the actual use needs. In terms of structural design, accessories often adopt reasonable cross-sectional shapes and wall thicknesses to ensure that they can still maintain stability and reliability when bearing high loads. In the production process, precision casting and processing technology are used to ensure that the dimensional accuracy and surface quality of the accessories reach high standards. These measures help to improve the strength and hardness of zinc alloy power tool accessories. The high strength and hardness of zinc alloy power tool accessories not only meet the basic requirements of power tools for the performance of accessories, but also bring users a safer and more reliable use experience. In power tools that rotate at high speed or work with high loads, high strength Accessories with higher hardness reduce the risk of wear and breakage, extend tool life and reduce maintenance costs.

Are You Interested In Our Products

Leave your name and email address to get our prices and details immediately.

English

English 中文简体

中文简体 Deutsch

Deutsch русский

русский