How can aluminum alloy profile electronic accessories achieve a double leap in high precision and high efficiency

16-07-20241. Drawing or sample stage

When receiving drawings or samples provided by customers, we take strict quality control measures. For drawings, we ensure that all dimensions are clear and accurate, the tolerance range is clear, and check their compliance with design requirements. For samples, we conduct all-round and high-precision measurements, including appearance dimensions, key feature points, material properties, etc., to ensure that the samples can accurately reflect the customer's design intentions. At the same time, we establish sample files and record various data of the samples in detail to provide a reliable reference for subsequent production. Through the fine operation of this stage, we have laid a solid foundation for subsequent high-precision production.

2. Drawing confirmation stage

Drawing confirmation is a key link to ensure smooth production. We use advanced CAD software to draw accurate 3D drawings based on the customer's 2D drawings or samples. In this process, we focus on communication with customers to ensure that both parties have a consistent understanding of the product design. We send the 3D drawings to customers and invite them to review and confirm in detail. We will respond promptly to any questions or modification opinions raised by customers during the confirmation process and adjust the drawings until the customer is satisfied. Through repeated communication and confirmation at this stage, we ensured the accuracy and completeness of the drawings, providing reliable guarantees for subsequent production.

3. Quotation stage

The quotation is an important link in reaching a cooperation intention with customers. After obtaining the drawings confirmed by the customer, we will conduct accurate cost accounting based on the design drawings and process requirements. Considering the production needs of high precision and high efficiency, we may adopt more advanced processing equipment and processes, which will increase certain costs. However, we always adhere to the principle of customer-centricity and strive to provide customers with competitive quotations while ensuring product quality. At the same time, we will also make reasonable suggestions and solutions based on the specific needs and budget of customers to facilitate cooperation between the two parties.

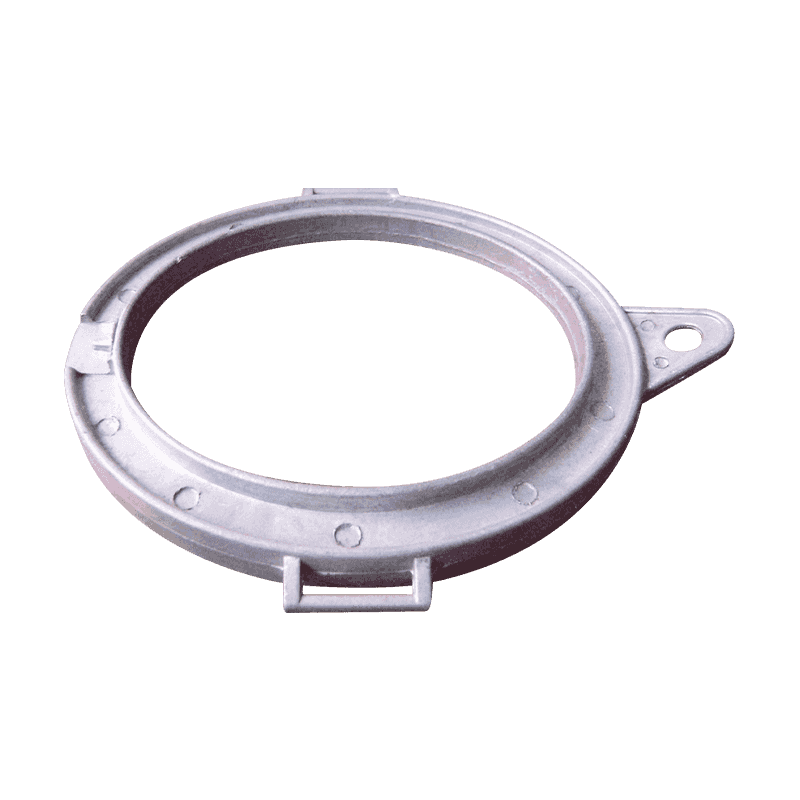

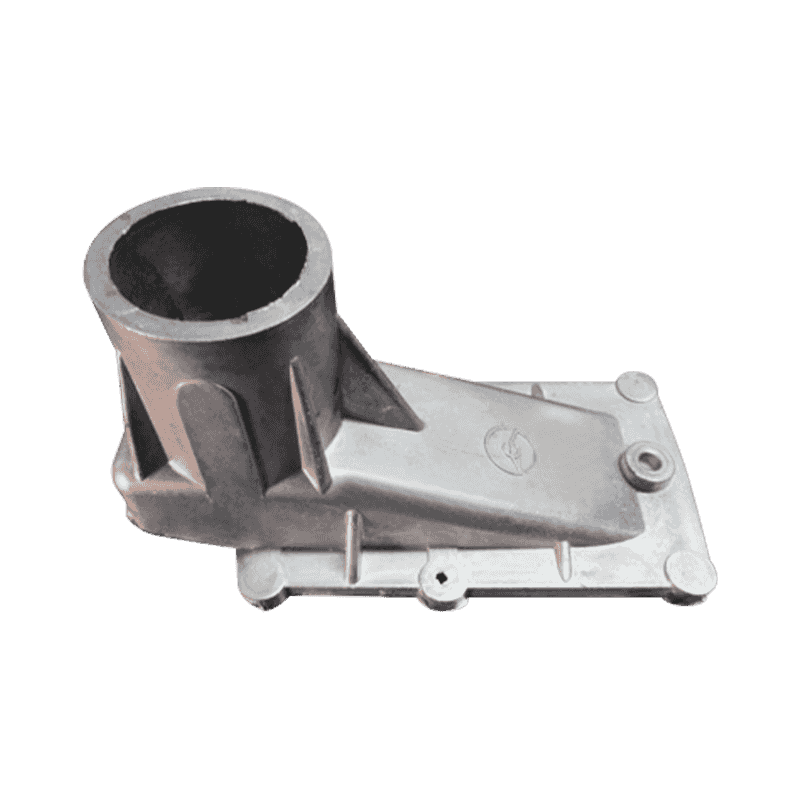

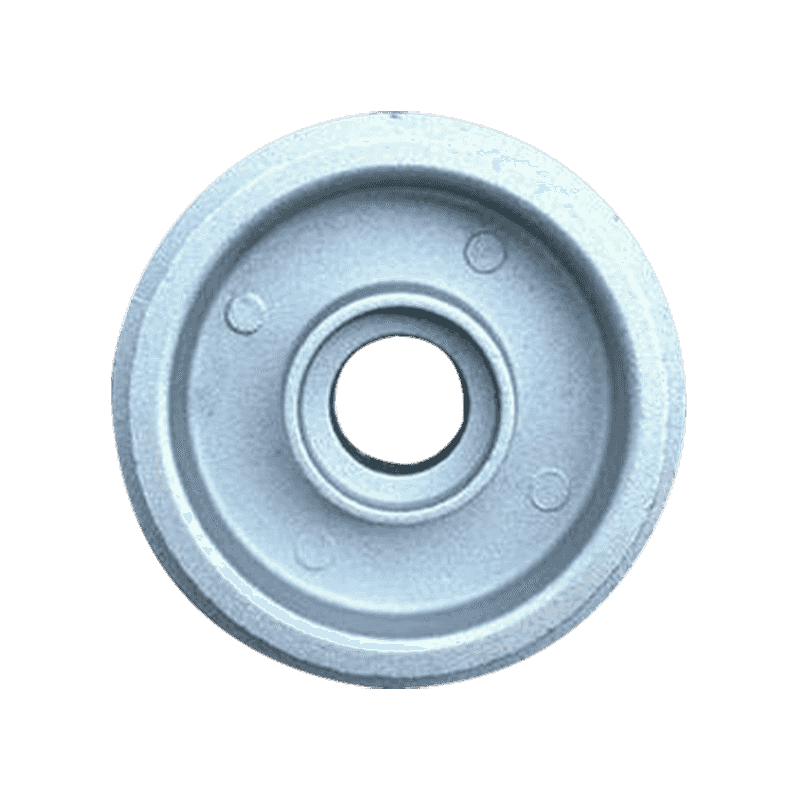

4. Mold/sample making stage

The mold or sample is a key tool for producing high-precision aluminum alloy profile electronic accessories. After receiving the customer's mold order, we immediately organize a professional mold making team to develop the mold or sample. We use high-precision CNC machine tools for mold processing to ensure the accuracy and durability of the mold. At the same time, we select high-quality mold materials, such as high-hardness alloy steel, to improve the service life and processing accuracy of the mold. During the mold making process, we pay attention to detail processing to ensure that every part of the mold meets the design requirements. After the production is completed, we will also conduct strict inspection and testing of the mold to ensure that it can meet the production needs.

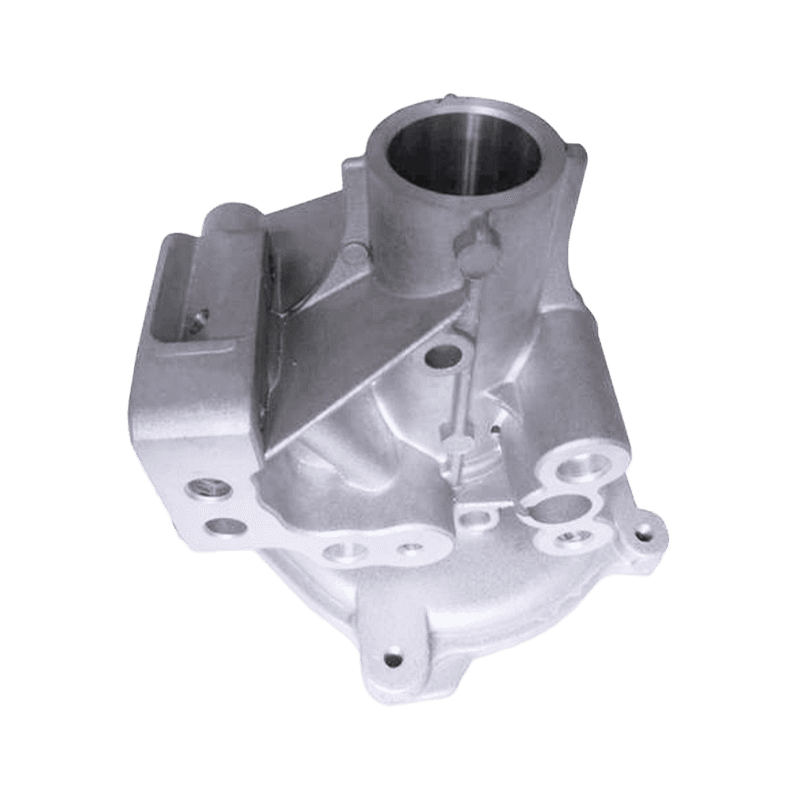

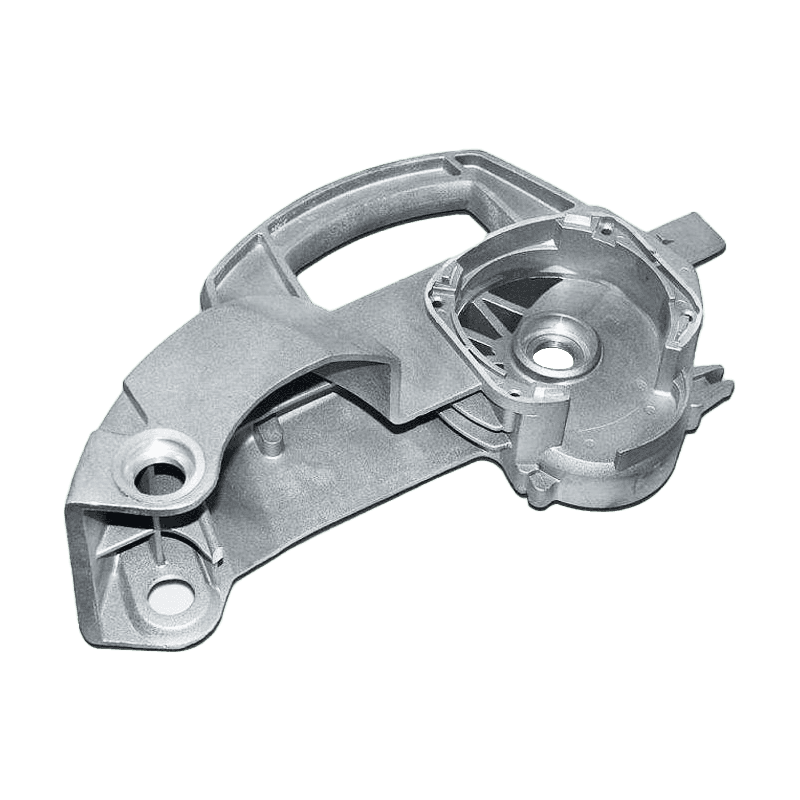

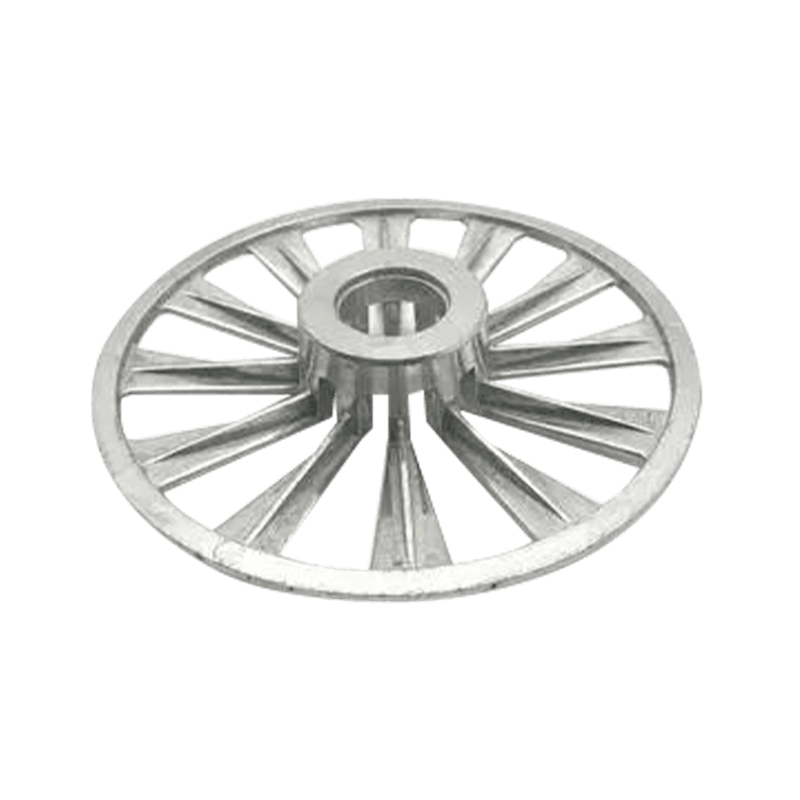

5. Sample making stage

Sample making is an important link to verify the accuracy of the mold and the quality of the product. We use strictly inspected molds to make physical samples and conduct comprehensive quality inspections on them. We use high-precision measuring tools to accurately measure the samples, including appearance dimensions, key feature points, material properties, etc., to ensure that the samples meet the design requirements. At the same time, we will also test the performance of the samples, such as strength, corrosion resistance, conductivity, etc., to ensure that they meet the actual needs of customers. After the sample is made, we will send the sample to the customer for confirmation in time. If the customer proposes modification suggestions, we will respond quickly and make corresponding adjustments and improvements until the customer is satisfied. Through strict control and continuous improvement at this stage, we ensure the high precision and high quality of aluminum alloy profile electronic accessories.

Are You Interested In Our Products

Leave your name and email address to get our prices and details immediately.

English

English 中文简体

中文简体 Deutsch

Deutsch русский

русский