The role and contribution of aluminum alloy die casting in the process of automobile lightweighting

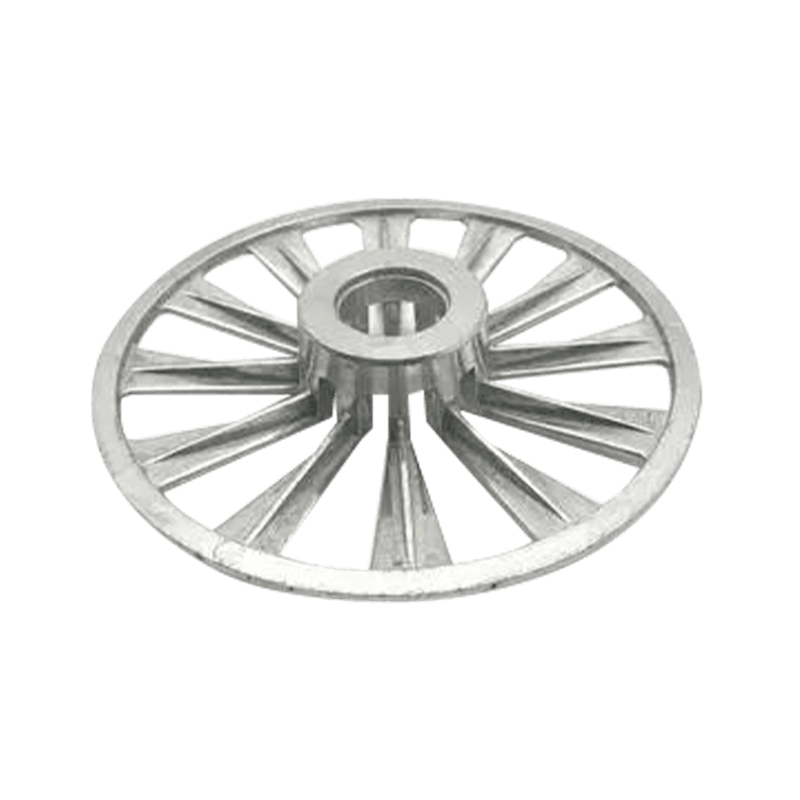

16-07-20241. Lightweight and high-strength to help reduce weight

Aluminum alloy die-casting occupies a core position in the automotive lightweight strategy due to its excellent lightweight and high-strength properties. As consumers have increasingly higher requirements for automobile fuel economy and environmental protection performance, reducing the weight of automobiles has become a key way to improve vehicle performance. Aluminum alloy die castings achieve significant weight savings by replacing traditional heavy materials such as steel. This weight reduction not only directly reduces the car's fuel consumption and emissions, but also improves the vehicle's acceleration performance and handling stability, giving drivers a more pleasant driving experience. At the same time, the high strength characteristics of aluminum alloy die castings ensure that they can reduce weight without sacrificing the structural safety and durability of the car.

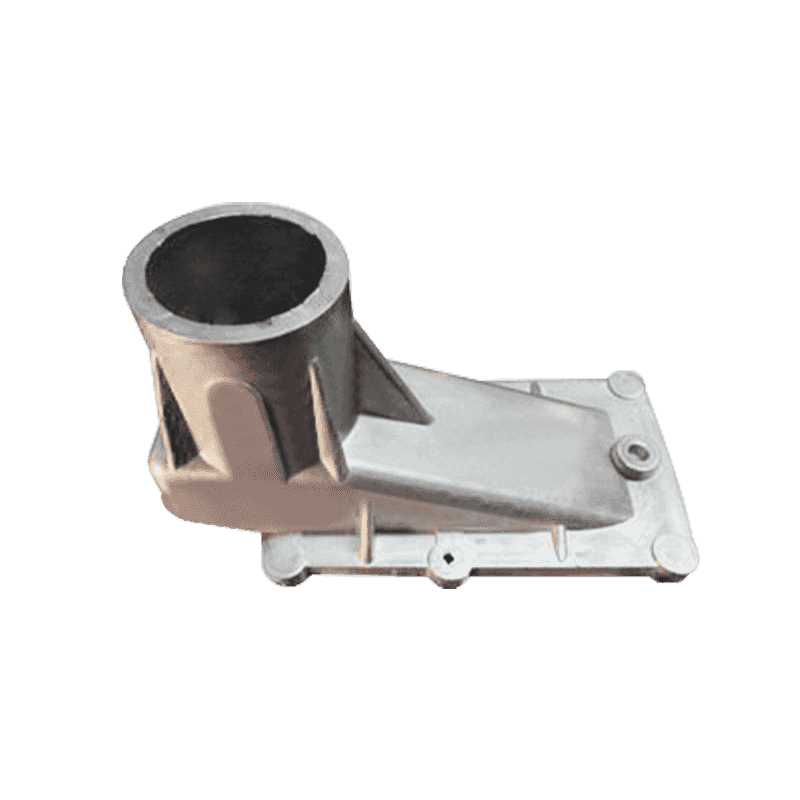

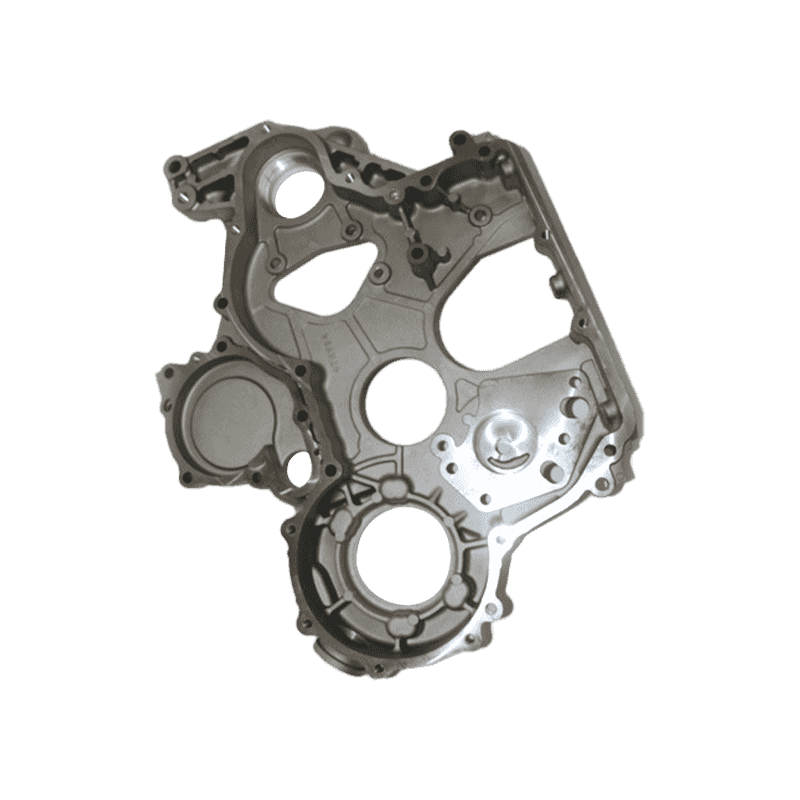

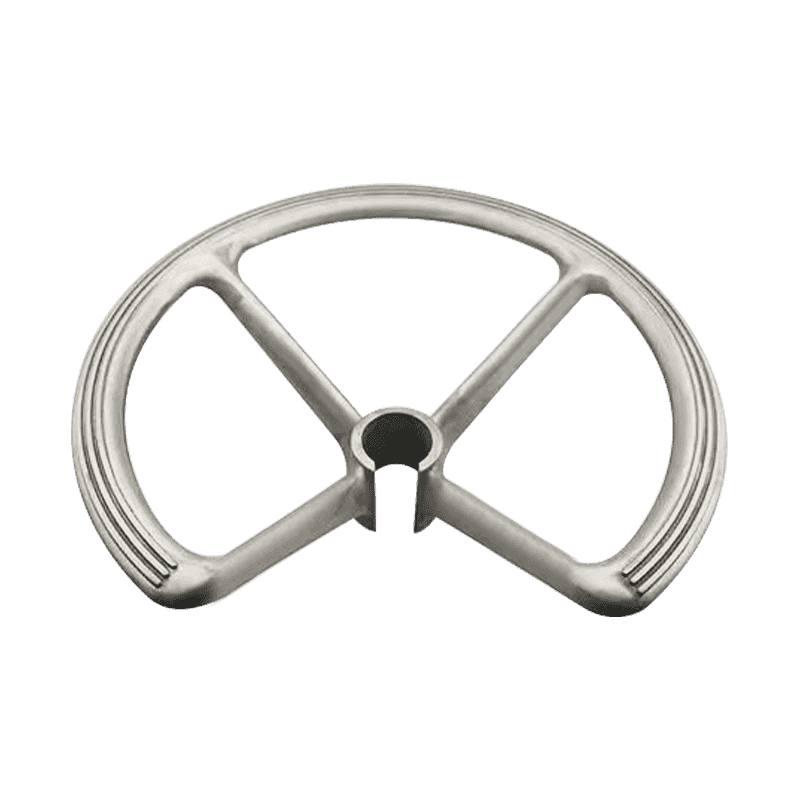

2. Complex structure, free design

Another significant advantage of aluminum alloy die-casting technology is its ability to manufacture parts with complex shapes and high design freedom. Traditional processing methods are often inadequate when faced with complex structures, while aluminum alloy die-casting technology can easily realize the manufacturing of various complex shapes and internal structures by virtue of its unique process characteristics. This provides car designers with a broad creative space, allowing them to design bodies and components that are more aerodynamic and beautiful. At the same time, the uniformity of wall thickness of aluminum alloy die-casting parts also ensures the strength and stiffness of the parts, improving the overall performance of the car.

3. High precision and improved quality

The high-precision characteristics of aluminum alloy die castings are one of the important reasons why they are so popular in automobile manufacturing. By precisely controlling mold design and process parameters, aluminum alloy die-casting technology can produce parts with precise dimensions and smooth surfaces. This high precision not only meets the strict requirements for parts in the automobile manufacturing industry, but also improves the overall quality and reliability of the car. During the assembly process, high-precision aluminum alloy die castings can reduce assembly errors and rework rates, improve production efficiency and reduce costs. At the same time, high-precision parts can also improve the driving stability and comfort of the car, giving drivers a more pleasant driving experience.

4. Efficient production and reduced costs

The efficient production characteristics of aluminum alloy die-casting technology give it significant cost advantages in automobile manufacturing. By using automated production lines and advanced production equipment, aluminum alloy die-casting companies can achieve large-scale, high-efficiency production. This efficient production not only shortens the production cycle, but also reduces production costs. At the same time, the quality of aluminum alloy die-casting parts is stable and reliable, reducing the scrap rate and rework rate, further reducing production costs. In addition, with the continuous development and improvement of aluminum alloy die-casting technology, its production efficiency and quality levels will continue to improve, bringing more cost advantages to the automobile manufacturing industry.

5. Environmentally friendly, sustainable and in line with development trends

In the context of the current global advocacy of environmental protection and sustainable development, aluminum alloy die-casting technology has received widespread attention for its good environmental performance. Aluminum alloy is a recyclable material, with a recycling rate of over 90%. After the car is scrapped, aluminum alloy die-casting parts can be recycled and reused to reduce resource waste and environmental pollution. In addition, the waste generated during the aluminum alloy die-casting process is relatively small and easy to dispose of. This environmentally friendly and sustainable feature makes aluminum alloy die-casting technology have broad development prospects in the automobile manufacturing industry. With the increasingly stringent environmental regulations and the continuous improvement of consumers' environmental awareness, aluminum alloy die-casting technology will play a more important role and make a more significant contribution in the process of automobile lightweighting.

Are You Interested In Our Products

Leave your name and email address to get our prices and details immediately.

English

English 中文简体

中文简体 Deutsch

Deutsch русский

русский